3 Operation

EN Concrete troweling BEG 90

14

Check fuel levels of petrol and oil.

(

!

HONDA GX 200 operating manual)

1.

Set the throttle lever [3, Fig. A] to the "idle

speed" position.

2.

Turn the motor switch [10, Fig. D] of the motor

[9, Fig. A/D] clockwise to the "ON" position.

3.

Open the petrol tap [12,Fig. D].

4.

Keep the dead man's switch [1,Fig. A] pressed.

5.

If the motor [9, Fig. A/D] is warm or the ambient

temperature is high, close the choke lever [11,

Fig. D] halfway or leave it fully open. If the en

gine is cold or the ambient temperature is low,

close the choke lever [11, Fig.D].

6.

Pull the starter handle [13, Fig. D] slowly until

resistance is felt. Return the handle to its origi

nal position and pull quickly.

Allow a longer warm-up phase in cold tem

peratures.

The machine is ready for operation.

3.2 Ending the operation

Never use the choke to switch off the engine!

1.

a.

Let the machine run at idle speed for 2-3

minutes to cool down.

b.

Set the throttle lever [3, Fig. A] to the "idle

speed" position.

c.

Release the dead man's switch [1,Fig. A].

d.

Turn the motor switch [10, Fig. D] located

on the motor [9, Fig. A] to the OFF position

to stop the machine permanently.

The motor [9, Fig. A] is switched off.

The operation is finished.

2.

Cleaning the machine.

3.3 Smoothing concrete

The operator must always be able to monitor

and control the machine!

The handle [2, Fig. A] must not be released

during operation!

The machine is ready for operation.

(

!

Chapter 3.1).

1.

Transport the machine to the place of use

before starting.

The motor [9, Fig. A] may not be tilted and

should always be transported and stored in the

working position!

a.

Hold the machine by the handle [2].

b.

Start the motor [9, Fig. A ].

(

!

HONDA GX 200 operating manual)

The motor [9, Fig. A] is switched on.

c.

Set the required speed on the accelerator

lever [3, Fig. A].

1

B

B

C

C

A

2.

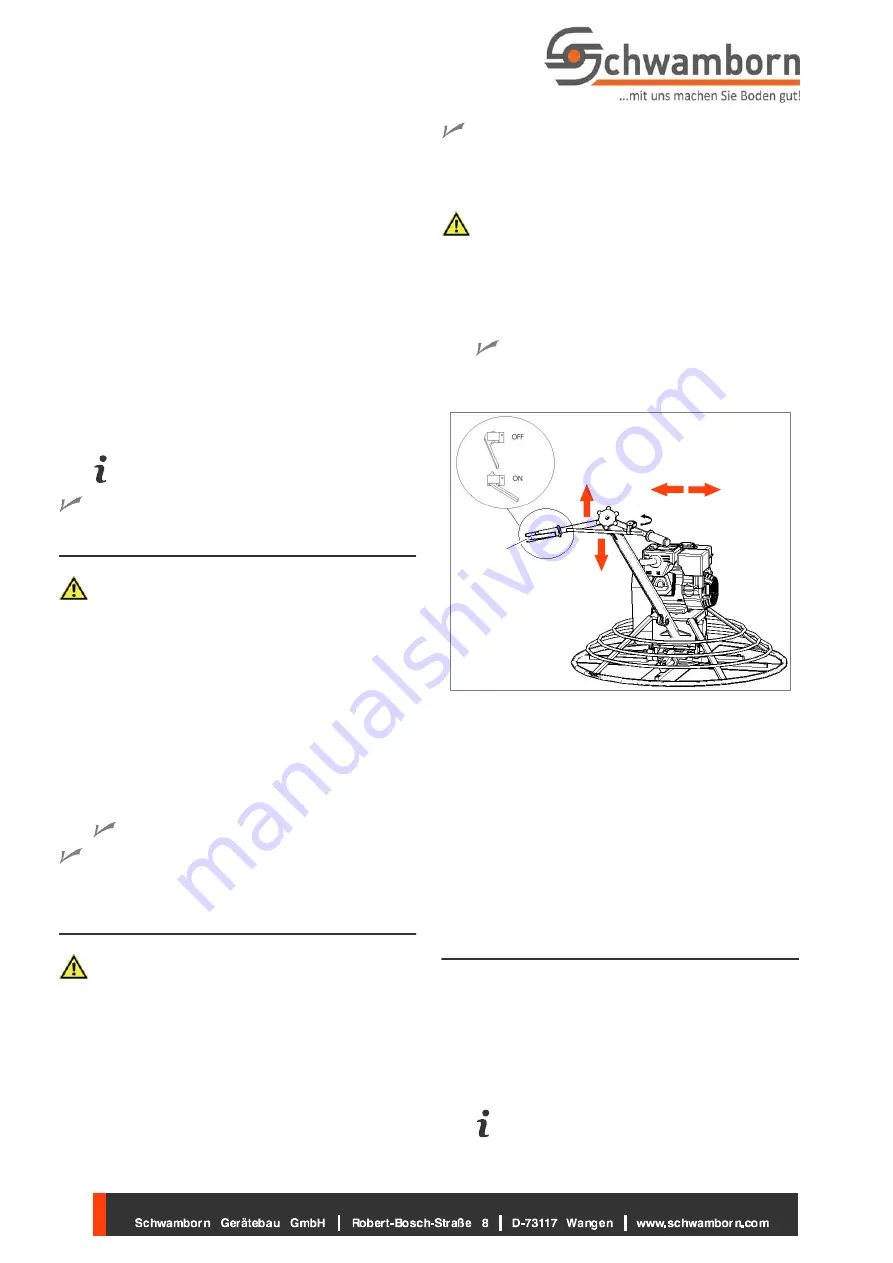

Hold the handle firmly and and have a secure

firm stand. Slowly operate the throttle lever [3,

Fig. A] until the desired speed is reached.

[(A) → see figure above]

3.

Press the handle down and the machine moves

to the right (B), lift the handle up and the ma

chine moves to the left (C). [→ see the figure

above].

Do not take bends!

4.

The machine remains in the same position if no

movements are made on the handle.

3.4 Blade adjustment

1.

The smoothing trowel adjustment [4, Fig. A/C]

has an infinitely variable adjustment that can be

made as required. During finishing work, the

setting can vary from area to area, depending

on the degree of hardening of the concrete. The

inclination setting can/must be changed ac

cordingly during machine operation.

When the concrete troweling is transported

on a truck, the blades [14, Fig. A] must al

ways lie completely horizontally flat on the

ground.

Summary of Contents for BEG 90

Page 2: ...2 3 1 4 9 5 2 6 7 8 Fig A Fig B 4 Fig C D D E E Fig D 13 11 10 10 12 14...

Page 19: ......

Page 20: ......