Page 5

Standard Schwinn pedals have threaded shafts that connect to the crank arms. The right pedal is

right-hand threaded while the left pedal is reverse threaded, meaning you turn to the left to tight-

en and right to loosen. For pictures of all different Schwinn pedals, see document

on our

support site. For a comprehensive list of accessories for Schwinn, see document

.

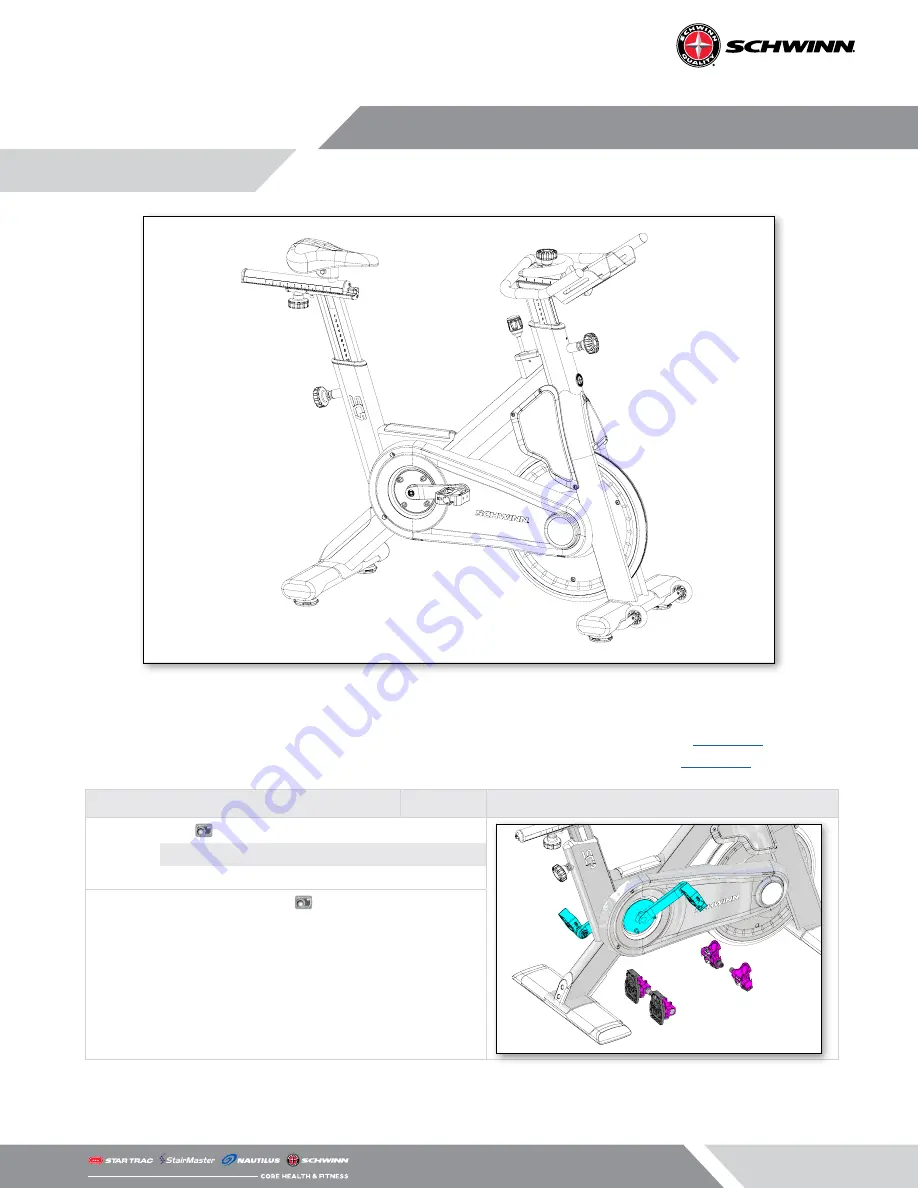

Cranks & Pedals

SKU

Power

4iiii

718-5765

KEO

DELTA

MPower

740-8941

Pedals

Standard Double Link

740-9020

Triple Link MT LOOK Delta-compatible

740-8689

Triple Link MT LOOK Keo-compatible

718-5869

ACCESSORIES