Bravo G4 17 / Bravo G4 22 / Bravo G4 28

EN

85

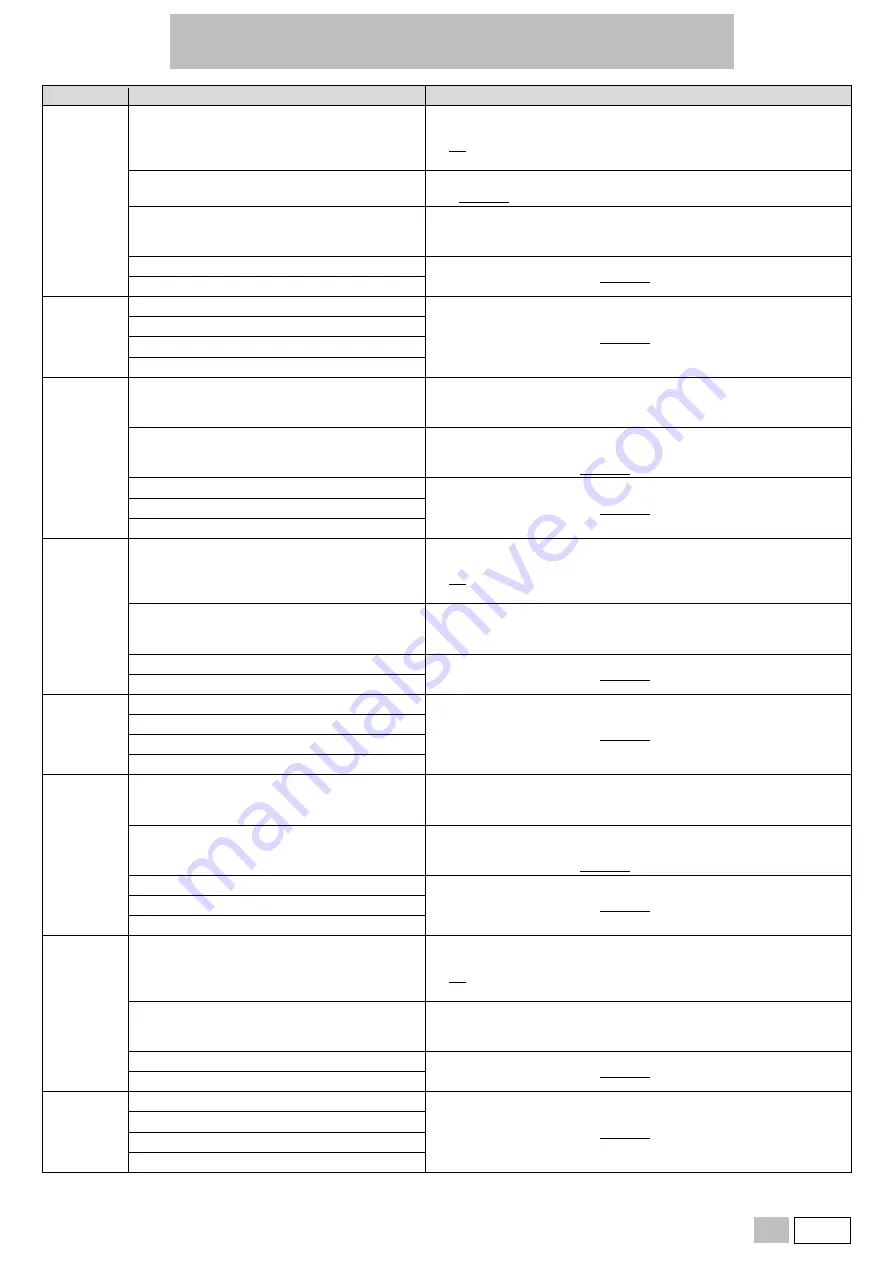

CODE

POSSIBLE CAUSE

SUGGESTED SOLUTION

A250

Water or condensate in the sterilisation chamber.

RESET according to the instructions.

Thoroughly dry the inside of the sterilisation chamber and restart the cycle.

Do not insert material impregnated with water or in general with liquids into the

chamber.

Drain filter obstructed.

Clean the drain filter.

(See Appendix Maintenance).

Air seepage through the gasket.

RESET according to the instructions.

Thoroughly clean the gasket with a clean cotton cloth moistened with water.

Restart the cycle.

Vacuum pump failure.

Contact Technical Service (see Appendix).

Problem in the hydraulic circuit.

A251

Water injection pump malfunction.

Contact Technical Service (see Appendix).

Problem in the hydraulic circuit.

Steam generator safety thermostat triggered.

Steam generator malfunction.

A252

Steam seepage through the gasket.

RESET according to the instructions.

Thoroughly clean the gasket with a clean cotton cloth moistened with water.

Restart the cycle.

Excessive load.

RESET according to the instructions.

Check that the load does not exceed the maximum values permitted.

(See the Summary Table in Appendix Technical Characteristics).

Problem in the hydraulic circuit.

Contact Technical Service (see Appendix).

Steam generator safety thermostat triggered.

Steam generator malfunction.

A253

Water or condensate in the sterilisation chamber.

RESET according to the instructions.

Thoroughly dry the inside of the sterilisation chamber and restart the program.

Do not insert material impregnated with water or in general with liquids into the

chamber.

Air seepage through the gasket.

RESET according to the instructions.

Thoroughly clean the gasket with a clean cotton cloth moistened with water.

Restart the program.

Vacuum pump failure.

Contact Technical Service (see Appendix).

Problem in the hydraulic circuit.

A254

Water injection pump malfunction.

Contact Technical Service (see Appendix).

Problem in the hydraulic circuit.

Steam generator safety thermostat triggered.

Steam generator malfunction.

A255

Steam seepage through the gasket.

RESET according to the instructions.

Thoroughly clean the gasket with a clean cotton cloth moistened with water.

Restart the program.

Excessive load.

RESET according to the instructions.

Check that the load does not exceed the maximum values permitted.

(See the Summary Table in Appendix Technical Characteristics).

Problem in the hydraulic circuit.

Contact Technical Service (see Appendix).

Steam generator safety thermostat triggered.

Steam generator malfunction.

A256

Water or condensate in the sterilisation chamber.

RESET according to the instructions.

Thoroughly dry the inside of the sterilisation chamber and restart the program.

Do not insert material impregnated with water or in general with liquids into the

chamber.

Air seepage through the gasket.

RESET according to the instructions.

Thoroughly clean the gasket with a clean cotton cloth moistened with water.

Restart the program.

Vacuum pump failure.

Contact Technical Service (see Appendix).

Problem in the hydraulic circuit.

A257

Water injection pump malfunction.

Contact Technical Service (see Appendix).

Problem in the hydraulic circuit.

Steam generator safety thermostat triggered.

Steam generator malfunction.