Bravo G4 17 / Bravo G4 22 / Bravo G4 28

EN

73

15. APPENDIX - GENERAL PROBLEMS

If while using the device a problem or an alarm occurs, this

DOES NOT

mean that the device is out of order.

It may not, in fact, be related to a breakdown but, more probably to an anomalous situation, often merely transitory (such as a blackout), or incorrect use.

In any case, it is important to first identify the cause of the failure and then take suitable corrective actions, either autonomously or with the intervention of

the

Technical Service Department

(see Appendix).

For this purpose, below, we provide instructions for diagnosing and resolving general problems, in addition to a precise description of the alarm codes,

their meaning and their solution.

15.1. TROUBLESHOOTING

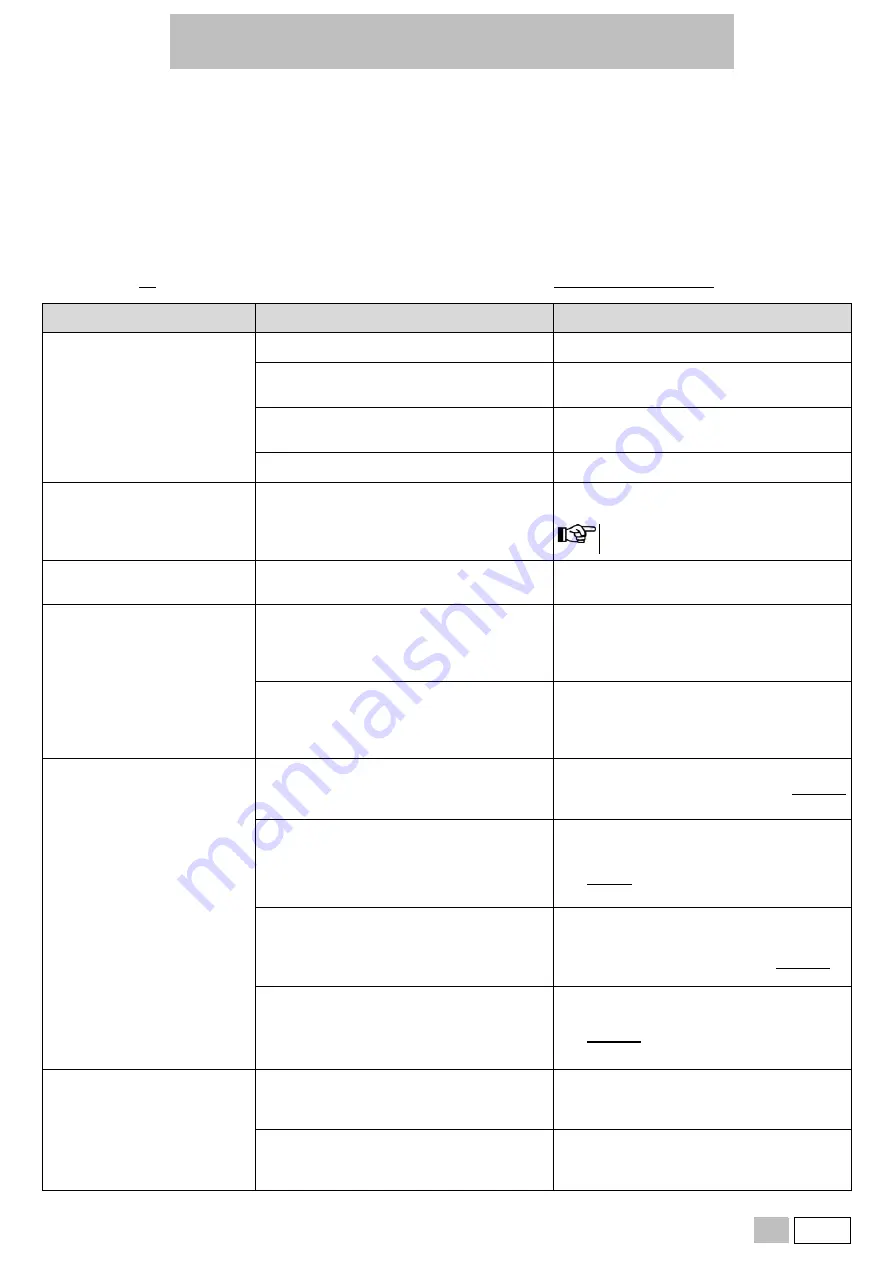

If your steriliser is not working correctly, please make the following checks before contacting the Technical Service Department:

PROBLEM

POSSIBLE CAUSE

SUGGESTED SOLUTION

The steriliser does not power-on.

The power cable is not plugged-in.

Plug it in.

Lack of voltage at the power supply socket.

Check the cause of the lack of voltage at socket and fix

it.

The main switch and/or differential switch are turned to

OFF.

Turn the switch to ON.

The mains fuses are blown.

Contact Technical Service.

After pressing START, the sterilisation

cycle does not start.

The device is preheating.

Wait for the steriliser to reach the proper operating

conditions for starting the program.

Under standard conditions, the Average

Preheating Time is about 10-15 Minutes.

The safety valve has triggered.

Locking ring loosened.

Presence of anomalous overpressure in the chamber.

Contact Technical Service.

Water presence on the steriliser

resting surface.

The water automatic filling system hose (optional) is

not correctly connected.

Check the tightness of the fittings and, if necessary,

reassemble them more carefully.

Check that the hoses are completely inserted on the

fittings; check the presence of hose clamps.

Steam leak from door gasket.

At the end of the cycle clean the gasket and the closing

porthole with a dampened cloth.

Check the presence of any gasket damage.

Perform a new verification cycle.

Excessive humidity on the material

and/or instruments at the end of the

program.

Excessive load in the sterilisation chamber.

Check that the load does not exceed the maximum

values allowed (See the Summary Table in

Appendix

“Technical Characteristics”

).

Load not correctly positioned.

Position the load, in particular the wrapped one, as per

the indications.

(See

Chapter

“

Preparing the material

”).

Wrong selection of the sterilisation program.

Choose the sterilisation program suitable for the type

of material to be treated.

(See the Summary Table in "

Programs

"

Appendix

).

Clogged chamber drainage filter.

Clean or replace the drainage filter.

(See

Appendix

“

Maintenance

”).

Traces of oxidation or spots on

instruments

Quality of the instruments not adequate.

Check the quality of instruments, making sure that the

material they are made of is suitable to tolerate the

steam sterilisation.

Organic or inorganic residues on the instruments.

Carefully clean the material before subjecting it to the

sterilisation cycle.

(See

Chapter “Preparing the material”).