SD-438 EU EN R5

8

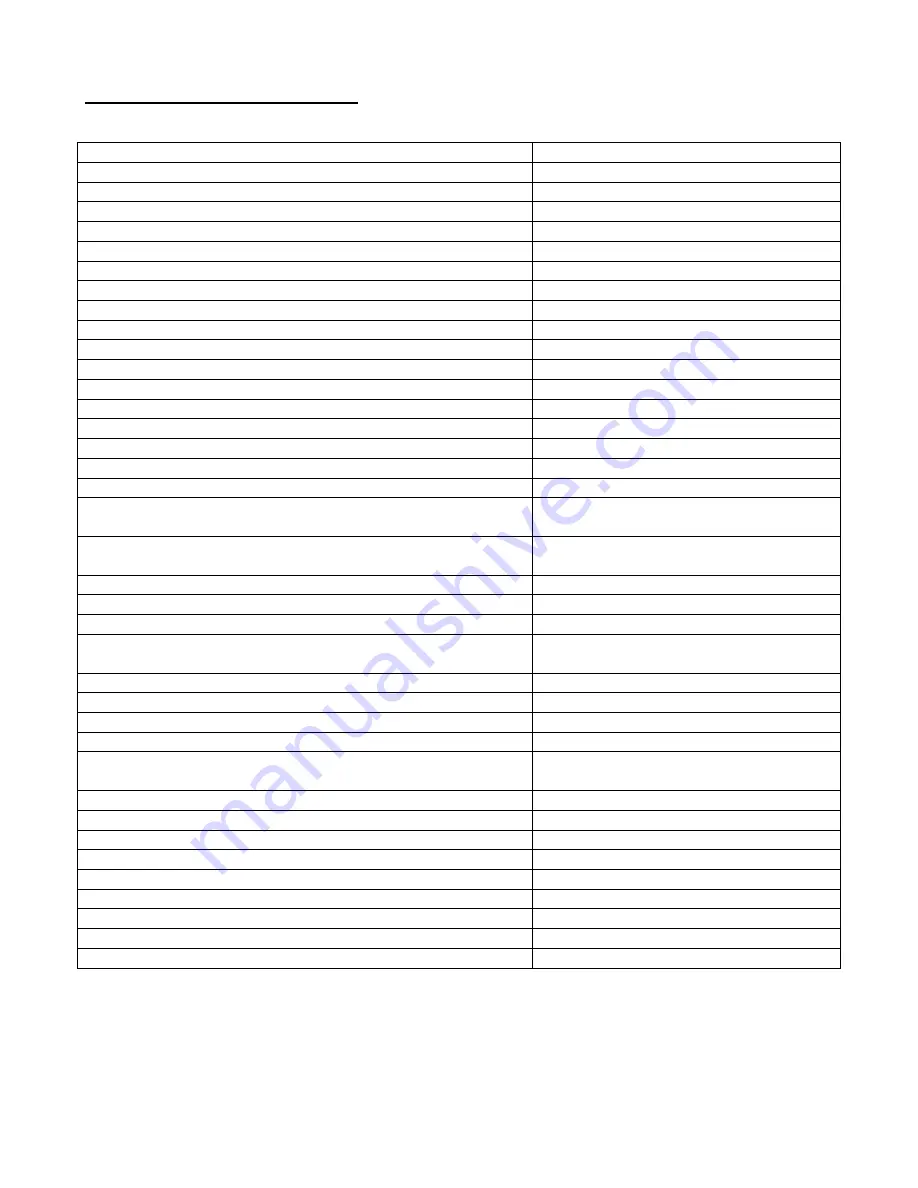

Technical Specifications Summary

HYDR

IM

C61wd G4

Applicable Standards

ISO 15883-1/2

Height

520 mm

Width

598 mm

Depth (Door closed)

598 mm

Depth (Door open)

829 mm

Weight

44 kg

Floor loading per support when full

152 N

Required clearance on top and sides

>10mm

Running Noise

65 dB(A)

Inlet water connections

G

¾

” or DN 20

Inlet water pressure

1-10 bar

Minimum water supply

HYDR

IM

C61wd G4: 2.5 L/min

Drain

¾

”

Maximum water flow to drain

47 L/min

Maximum water discharge temperature to drain

95°C

Maximum water hardness

30.3°dH, 31.6 US GPG, 540 PPM

Maximum water conductivity

844

µ

S/cm

pH range

>6.8 and < 8.5

Water volume per process stage

3.8 L ± 0.5 L

P3 has additional 18.9 ± 1L for drying

Total water consumption per cycle with drying

P1 & P2: 11.4 L ± 1.5 L

P3: 30.3 L ± 2.5 L

Maximum heat transmitted through fascia

1200 W

Water softener salt capacity

0.5 kg / 1.1 lbs

Equipment installation category

II

Voltage*

208 – 240 VAC, OR

200 – 230 VAC ± 10%

Frequency*

50 Hz or 60 Hz

Rated load

2.7 kW

Current

12A

Operating temperature range

5°C – 40°C

Maximum relative humidity

80% for temp up to 31°C

50% for temp up to 40°C

Maximum operating altitude

2000 m

Equipment pollution degree

2

Maximum deviation from plane horizontal surface.

2mm

Suitable process chemicals for each stage

HIP Ultra

Total amount of process chemical

43.5 mL

Material Safety Data Sheet

Refer to download page of website

Cycle recording options

USB, G4 web portal, external printer

Air pressure range (LCS Model Only)

1 bar (15 PSI) - 10 bar (145 PSI)

Compressed air connection

DN 7.2

*Refer to Electrical Supply table