69

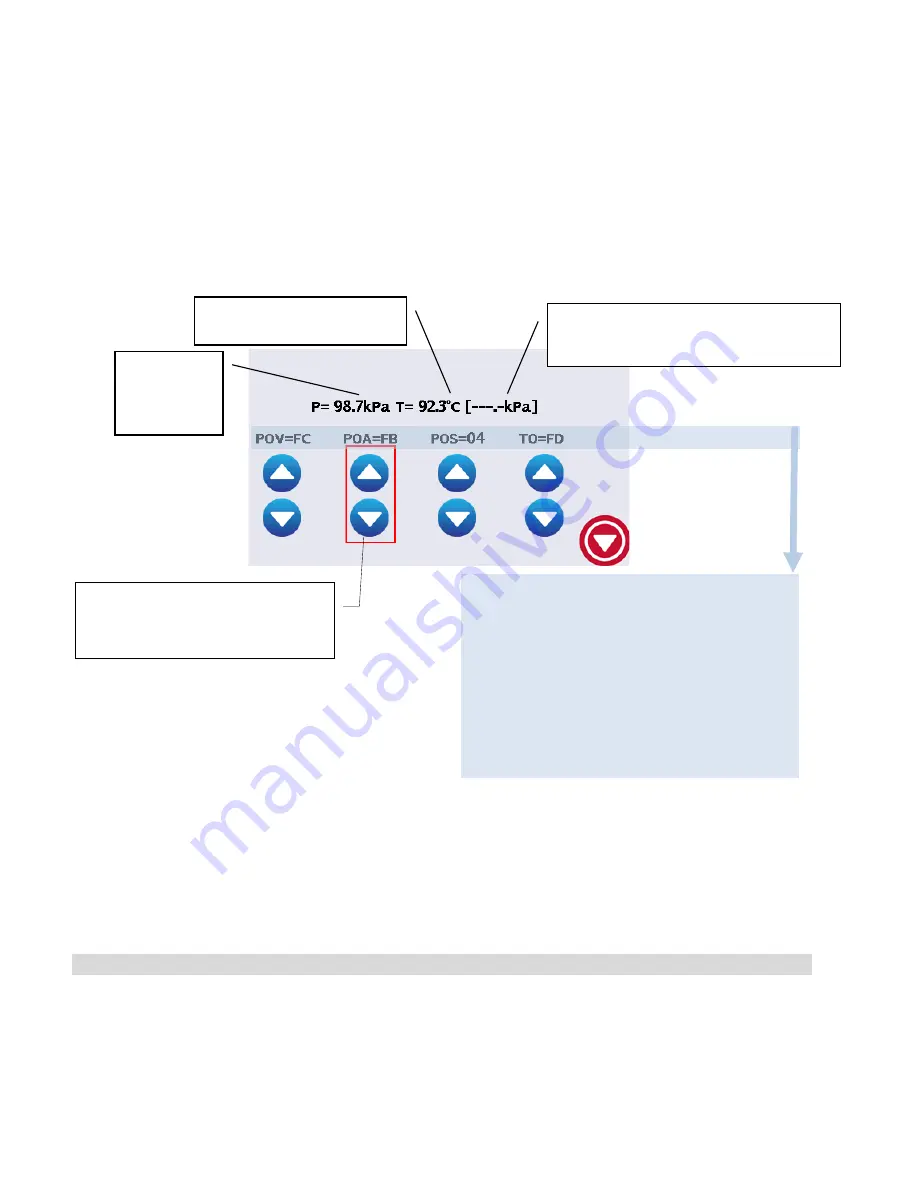

To complete the

POA

calibration, compare the pressure reading on the display (

P

) with the pressure reading

on the pressure reference meter. (See the following Step for a full explanation of the calibration screen.)

Adjust the pressure reading using the up or down arrows on the

POA

offset field.

NOTE: The difference in two readings should be within 0.5Kpa. If the two readings cannot be matched

precisely, set pressure reading on unit to one count below the reading on the pressure reference

meter.

13.

Explanation of the calibration screen:

14.

After completing the POA calibration, use the arrows below the

POS

and

TO

values to set them to

00

,

if the displayed values are not already 00.

NOTE: Offset adjustment arrows DON’T have to be highlighted to change values.

STAGE 4. Adjusting the pressure at vacuum

15.

The cycle then continues to the vacuum phase. The

POV

field on the display will be highlighted.

16.

Wait for the vacuum to reach

60 Kpa or less

. Once the vacuum is in this range, compare the reading

on unit’s display (

P

)

with the reading on pressure reference meter. The pressure reading can now be

adjusted by using the up or down arrows on the

POV

field

.

A red rectangle highlights the offset to

be adjusted at each stage of the

calibration.

Actual

Chamber

Pressure

Actual Chamber Temperature

Calculated Chamber Pressure (Calculated

from chamber temperature)

The abbreviation definitions are as follows:

POV

-

Pressure offset at Vacuum

POA

-

Pressure offset at Atmosphere

POS

-

Pressure Offset at Sterilization

Temperature

TO

-

Chamber Thermocouple Offset

Summary of Contents for STATCLAVE G4

Page 5: ...5 Diagram of key systems and components...

Page 6: ...6...

Page 17: ...17 Checking package contents...

Page 18: ...18 Positioning a unit Unit dimensions and operating environment...

Page 20: ...20 Direct to drain connection recommended...

Page 21: ...21 Connecting to a waste bottle...

Page 22: ...22 Connecting to the Internet Connecting to a wired network Connecting to a wireless network...

Page 23: ...23...

Page 25: ...25 Connecting an auxiliary pump...

Page 28: ...28...

Page 30: ...30 Starting and stopping a cycle...

Page 50: ...50 Registering for online access...

Page 51: ...51 First start up...

Page 52: ...52...

Page 58: ...58 Draining the unit for cleaning and shipping...

Page 61: ...61 Replacing the bacteriological filter Replacing the door seal...

Page 75: ...75...

Page 107: ...107 APPENDIX A STATCLAVE G4 plumbing diagram...

Page 108: ...108 APPENDIX B STATCLAVE G4 electrical schematic...