70

NOTE: The

POV

offset will be adjusted again at Step 26 of the calibration process when the unit reaches a

pressure (vacuum) value in the region of

20kPa (30kPa or less)

.

17.

On completion of the vacuum phase, the unit will go back to atmospheric pressure. Check the readings between

the unit’s pressure display (

P

) and the pressure reference meter. The two readings should still be within

0.5Kpa

.

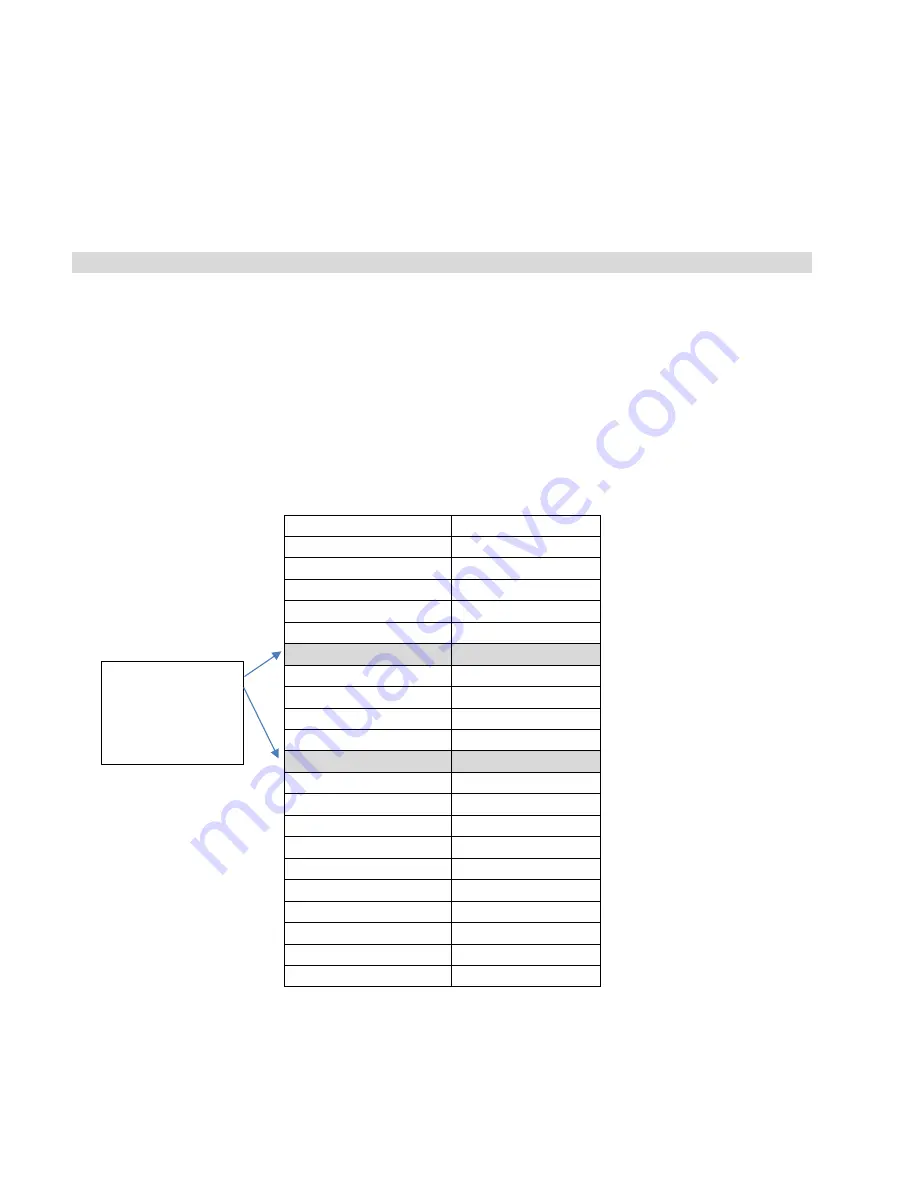

STAGE 5. Checking your reference meter values using the steam saturation table

18.

The unit will now start to heat up to 120°C for the first time. This is the first pressure pulse. It will be

followed by a vacuum pulse and then the pressure and temperature will begin to increase again.

CAUTION! The Teflon tubing connecting the test port to the pressure reference meter will

become hot.

19.

When the reference meter reaches 125°C, you can verify that the steam saturation level is correct by

checking the temperature and pressure values on your reference meters against the table below. Check

again at 130°C.

To check the values, read the temperature on your reference meter and make sure that the pressure

reference meter is reading a value that is within 3 kPa from the corresponding pressure value in the

table. For example, at 125°C your corresponding pressure value should be no lower than 229.24 and

no higher than 235.24.

Temperature (°C)

Pressure (kPa)

120

198.67

121

205.05

122

211.59

123

218.3

124

225.18

125

232.24

126

239.47

127

246.89

128

254.5

129

262.29

130

270.28

131

278.46

132

286.85

133

295.43

134

304.23

135

313.23

136

322.45

137

331.88

138

341.54

139

351.43

140

361.54

20.

If your reference meters DO show that your temperature and pressure values match with the steam

saturation table, continue to the next step.

Check reference

meter values

here

Summary of Contents for STATCLAVE G4

Page 5: ...5 Diagram of key systems and components...

Page 6: ...6...

Page 17: ...17 Checking package contents...

Page 18: ...18 Positioning a unit Unit dimensions and operating environment...

Page 20: ...20 Direct to drain connection recommended...

Page 21: ...21 Connecting to a waste bottle...

Page 22: ...22 Connecting to the Internet Connecting to a wired network Connecting to a wireless network...

Page 23: ...23...

Page 25: ...25 Connecting an auxiliary pump...

Page 28: ...28...

Page 30: ...30 Starting and stopping a cycle...

Page 50: ...50 Registering for online access...

Page 51: ...51 First start up...

Page 52: ...52...

Page 58: ...58 Draining the unit for cleaning and shipping...

Page 61: ...61 Replacing the bacteriological filter Replacing the door seal...

Page 75: ...75...

Page 107: ...107 APPENDIX A STATCLAVE G4 plumbing diagram...

Page 108: ...108 APPENDIX B STATCLAVE G4 electrical schematic...