StatClean Audit Procedure - Foil Test

Ultrasonic cleaners shall be tested at least weekly for cleaning performance as per the protocol

recommended in the manufacturer’s instructions for use. The test results shall be documented.

Procedure:

1.

Remove the lid, basket, containers and any beakers.

2.

Clean the tank thoroughly.

3.

Fill the tank with water to its max fill line and add an instrument cleaning solution, we recommend

OPTIM 28 (do not replace the basket).

4.

Take a piece of autoclave tape and run it from the left hand front corner to the right hand back

corner.

5.

Obtain a piece of standard household aluminum foil and cut 3 pieces 2cm (3/4”) wide and 14cm (

5.5” ) long. Fold each piece to L shape along the length.

6.

Stick the 3 pieces evenly spaced from left to right across the center of the tank, sticking the

end to the the underside of the tape. Keep the foil vertically into the water with the bottom edge

approximately 1cm (1/2”) above the bottom of the tank.

7.

Replace the lid on the unit.

8.

Turn on the ultrasonic machine and run for 1 minute.

9.

Once the time has been reached, stop the unit and remove the lid.

10.

Remove the foils and inspect. The foils should be perforated along the 3 edges with more damages

toward the bottom.

11.

If either one on the left or the right has no obvious perforations, the transducer near that foil may

not be working properly. Call for service if this happens.

13

CARE AND MAINTENANCE

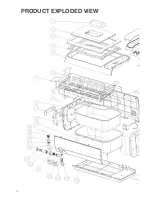

Summary of Contents for StatClean SC-P4862

Page 2: ......

Page 14: ...10 PRODUCT EXPLODED VIEW...