Page 209

STAT

IM 2000/2000S

Service Guide

96-106775 Rev 5.0

10. Armature, Isoplate, and Probe Bracket and Chamber Thermocouple

STAT

IM

5000/5000S/5000 G4 Service Guide

Reinstalling the armature and isoplate

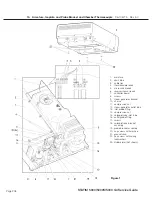

To reinstall the armature (1), proceed as follows (see Figure 1):

1. Align the armature (1) with the chassis (13). Tilt the unit sideways with the reservoir and PCB

facing upwards, insert and tighten the four cap screws with spring lockwashers (22) retained

from the removal procedure. Ensure that the armature drain tube exits through the hole in the

chassis.

IMPORTANT: Be careful not to cross-thread the cap screws in the tapped holes of the

armature.

Be careful not to damage the armature drain tube, the thermocouple in the probe bracket

assembly, the ground strap or the bubble level (23).

2. Install the probe bracket assembly (19). Partially insert the two bottom cap screws and attach

the ground strap (21) to the bottom right hand position of the probe bracket assembly before

proceeding.

3. When the lower screws securing the probe bracket assembly are installed, tighten the cap

screws with washers holding the armature to the chassis.

4. CAREFULLY bend the thermocouple leads back into position.

5. Complete installation of the probe bracket assembly (19). (See, Probe Bracket and Chamber

Thermocouple Subassembly below).

6. Secure the solenoid valve assembly (18).

7. Tighten the two screws (11) holding the steam generator bracket (12) to the chassis (13).

8. Bundle the microswitch leads (5), thermocouple leads (4) and the reservoir sensor leads (6)

together using cable ties every 2-3 inches. Secure the wires and thermocouples to the top of

the armature using the cable tie anchors provided on top of the armature.

9. A dielectric strength test (Hi-Pot) and a protective bonding impedance test (ground continuity)

should be performed on the STAT

im

unit at this stage.

NOTE:

These tests must be performed on the STAT

im

again once the work is completed and

the cover has been returned to the unit.

10. Check that the bubble level (23) on the front right top corner of the armature is not damaged

and that the bubble moves freely.

11. Refill the reservoir using steam process distilled water.

12. Calibrate the thermocouples appropriate to the unit type.

13. Run a sterilization cycle and observe all fittings and tubes for leaks. Check LCD read-outs for

messages indicating cycle status.