12

Error codes

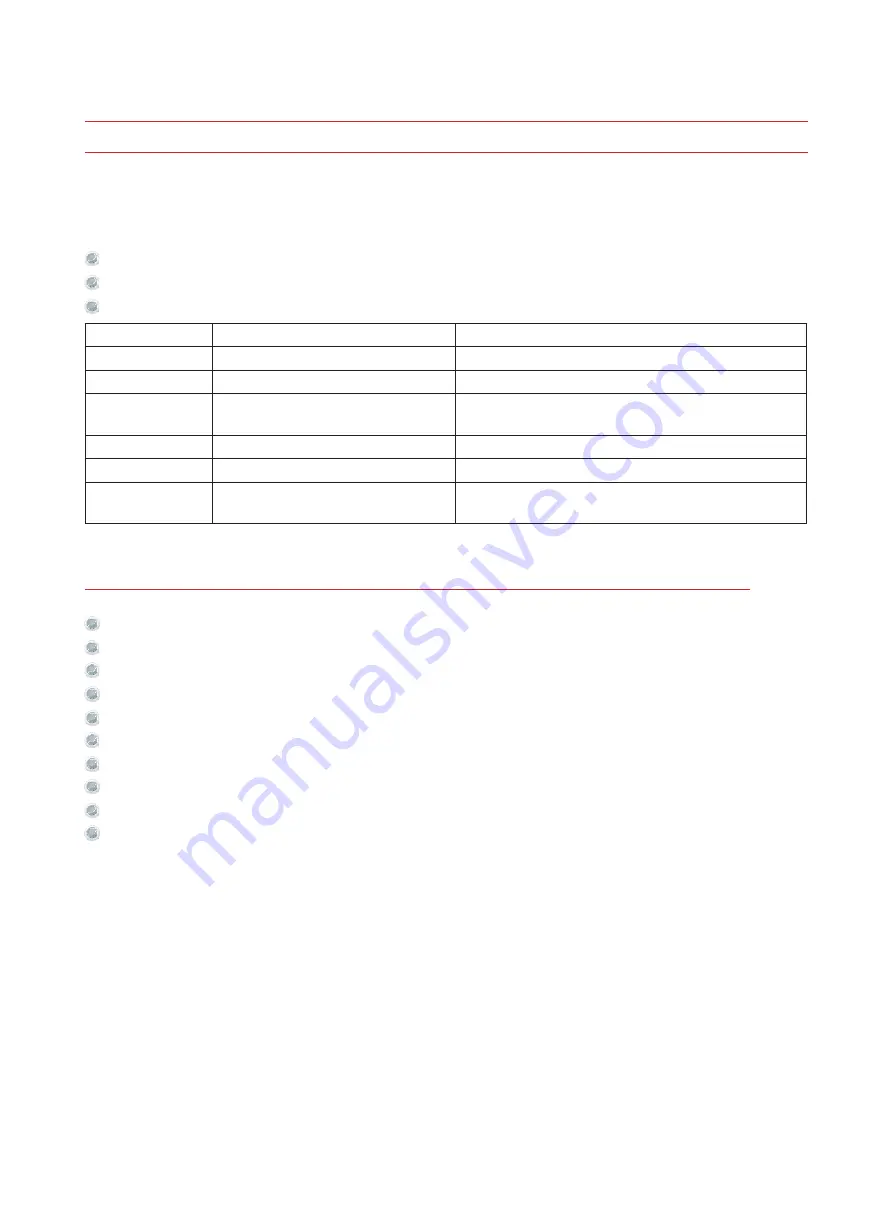

Any error happen, the device will stop circulation and heating,beeper on and show the error message on

the display.

Proceed as followings in such cases:

Turn off the device and pull the plug.

Carry out corrective measures.

restart

the device.

Error code

Cause

Solution

Er00

Interal temp. sensor error

Restart the device.

Er01

External temp. sensor error

Check the connection of the sensor.

Er02

Cooling system over presssure

Switch off the device 1 hour for cooling down,

clean the ventilation mesh.

Er03

Communication time out

Check the connection of the Data cable.

Er04

Low liquid

Check the liquid level of the bath vessel.

Er05

Over temperature

Check the over temperature setting value;

Check the Temperature sensor and the heater.

Please contact us if the corrective action described fail.

Maintains

Do not impact the device, especially the control panel.

Please check the device before start up.

Please check the control panel and warning labels every functional periodic (every half year).

Operation (ambient) temperature range: Max. 32℃ , Min. 5℃ . Max humidity:50% (40℃ )。

Only operate the unit in rooms that are well-ventilated, dry and free of frost.

Do not expose the device directly under sunlight.

Ensure good PE connection of the device.

Turn off the device before any cleaning / servicing / maintains.

Drain

the unit completely before transporting it.

Do not start the unit if it is damaged or leaking.

Summary of Contents for SCIP5-Mini

Page 1: ...Operation Manual Ver 1 7...