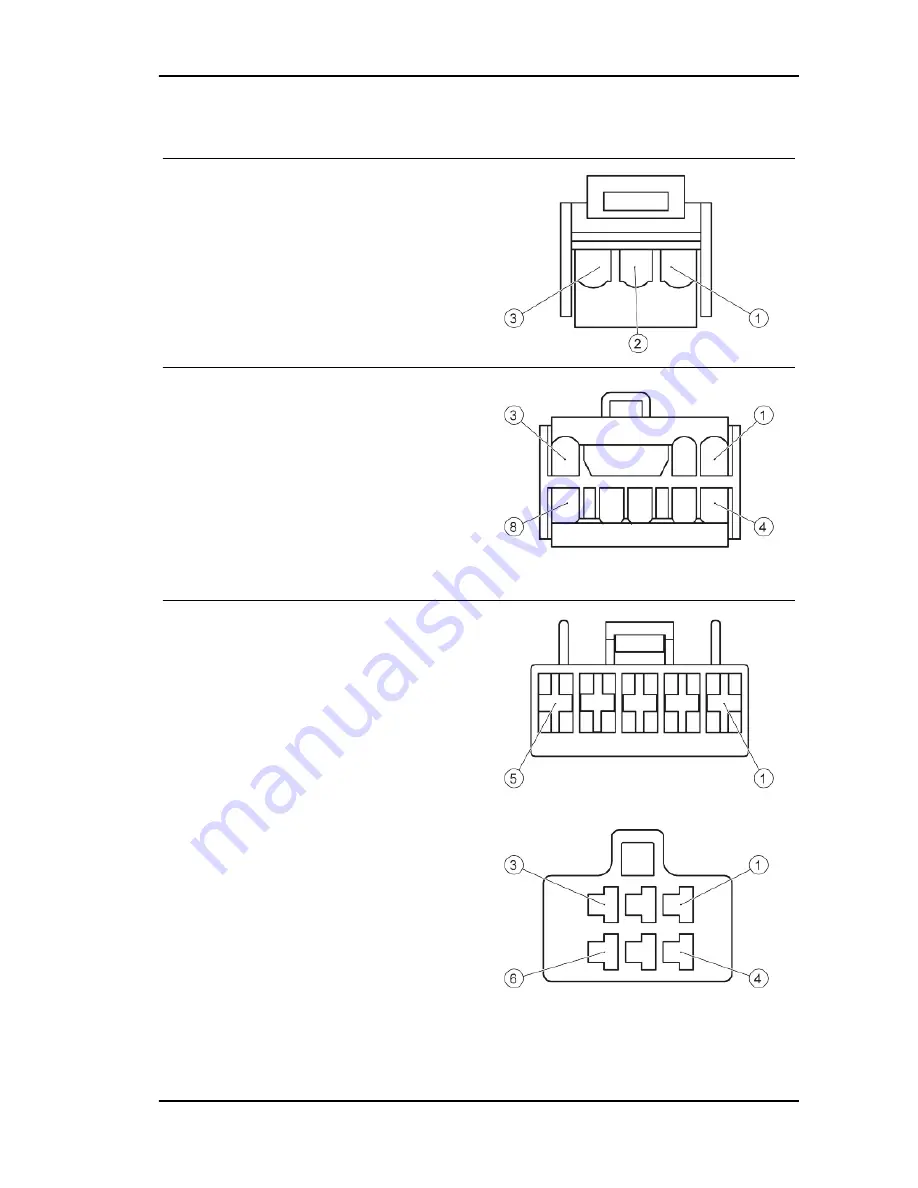

Connectors

ELECTRONIC STARTER

CONNECTOR A

1. H.V. coil control (Black):

2. Engine stop command (Blue)

3. H.V. coil positive (Violet)

CONNECTOR B

1. Key positive (Orange-Black)

2. Starter power (White-Black)

3. Pick-Up Signal (Green)

4. Ground lead (Black)

5. Solenoid valve (Brown)

6. NTC temperature sensor signal (Yellow-Red)

7. Lights logic solenoid command (Light Blue)

8. Diagnostics socket (Red-Black)

VOLTAGE REGULATOR

1. Lighting system power (alternating) (Yellow)

2. Ground lead (Black)

3. Battery positive (live) (Orange)

4. Flywheel power (alternating) (Blue)

5. Turn indicator power (Blue-Black)

Fly 50 4t 4v

Electrical system

ELE SYS - 91

Summary of Contents for Fly 50 4t 4v

Page 1: ...WORKSHOP MANUAL 677586 EN Fly 50 4t 4v ...

Page 4: ......

Page 6: ...INDEX OF TOPICS CHARACTERISTICS CHAR ...

Page 28: ...INDEX OF TOPICS TOOLING TOOL ...

Page 37: ...INDEX OF TOPICS MAINTENANCE MAIN ...

Page 49: ...INDEX OF TOPICS TROUBLESHOOTING TROUBL ...

Page 53: ...Fly 50 4t 4v Troubleshooting TROUBL 53 ...

Page 54: ...INDEX OF TOPICS ELECTRICAL SYSTEM ELE SYS ...

Page 63: ...7 Start up solenoid 8 At the battery connections Fly 50 4t 4v Electrical system ELE SYS 63 ...

Page 93: ...INDEX OF TOPICS ENGINE FROM VEHICLE ENG VE ...

Page 99: ...INDEX OF TOPICS ENGINE ENG ...

Page 158: ...INDEX OF TOPICS SUSPENSIONS SUSP ...

Page 173: ...INDEX OF TOPICS BRAKING SYSTEM BRAK SYS ...

Page 181: ...Fly 50 4t 4v Braking system BRAK SYS 181 ...

Page 182: ...INDEX OF TOPICS CHASSIS CHAS ...

Page 203: ...INDEX OF TOPICS PRE DELIVERY PRE DE ...

Page 208: ...V Vehicle 8 94 169 ...