ScopeDome.com

2010 Slupsk - Poland

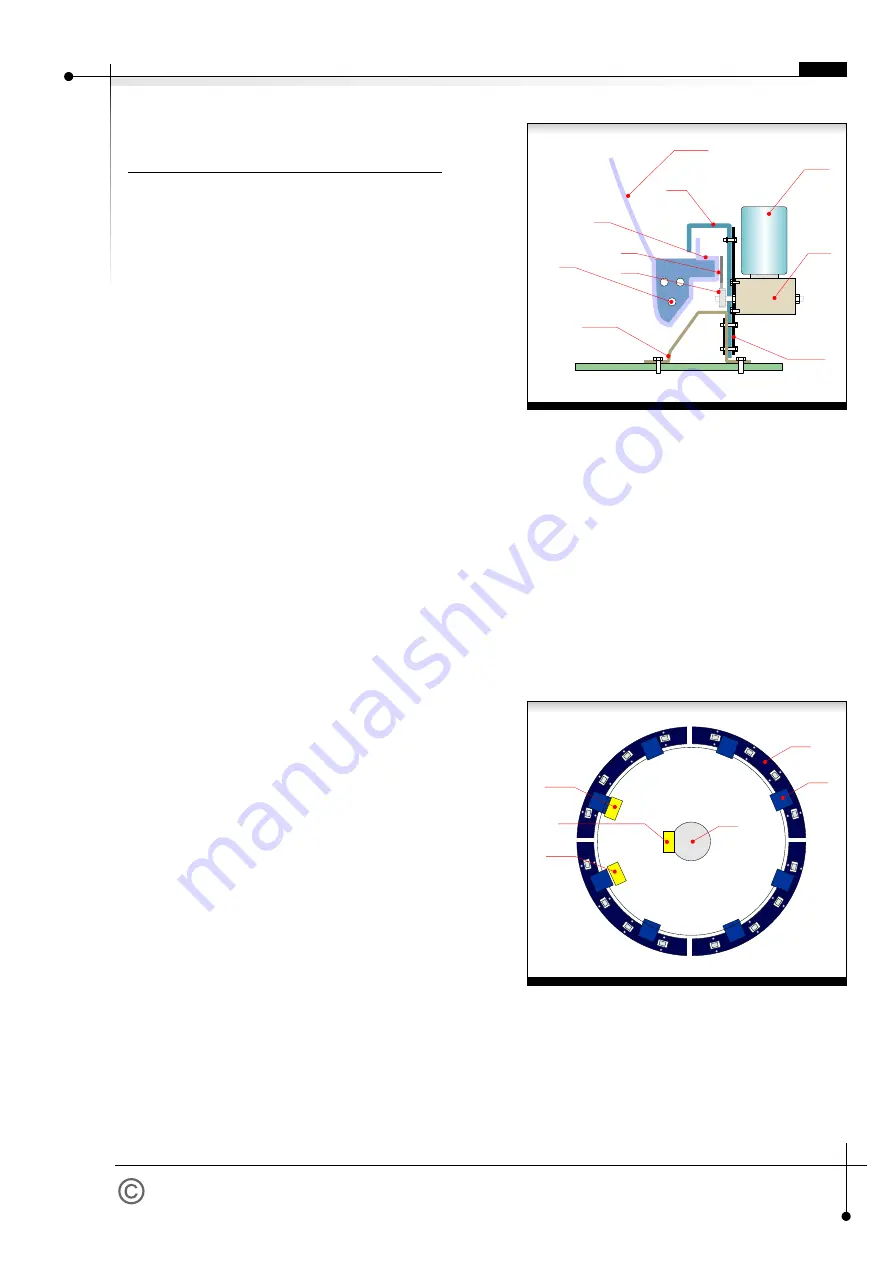

Electronics and driving systems fittings

F

G

A

C

H

D

B

I

J

Fig. 13 - Dome's driving motor system

scheme

A. Dome's side wall panel

B. Base ring

C. Cog-rim drive shield

D. Cog-wheel

E. Cog-rim

F. Motor ( engine)

G. Motor reductor (gear) (1/50)

H. Engine's mounting plate

I.

Driving ring

J. Driving ring bolt holes

C

D

E

F

A

B

Fig.14 - Electrical installation diagram

A. Base ring

B. Cog-rim drive shield support/holder

C. Main power supply box

D. ScopeDome Card

E. Driving motor system with roller

F. Pier (a telescope basis)

page 8

E

Electronics and driving systems

fittings

Tip:

Tip:

-

Do not install shutter driving wire cables until you test

the shutter motor system end switches action and

the whole electronics.

-

Before you install the drivers and electrical

components, it is recommended to wash the dome

using a garden hose. Without this operation

removing the remains and debris will require much

more effort.

1. Fit encoder sensor (see fig 6). Start to rotate the

dome carefully, focusing your attention on possible

cog-rim abrasion. Encoder could be damaged very

easily if such abrasion appears.

2. Fit contactron "home" on drive shield.

3. Fit end switches on the front and the top of the

shutter window.

4. Fit the end switches pressing plate on the shutter in

a way that limit switches activate at about 2 cm

before full closing or full opening of the shutter.

5. Put contactron "home" magnet on the dome's back

at the distance from contactron "home" allowing

contactron's switches to be active as briefly during

the dome's rotation, as possible.

6. Stick encoder cleaning tape to cog-rim (see fig 10) at

contactron magnet (Home Sensor) height.

7. Fit the cable box on the rotary part of the dome.

8. Fit the ScopeDome Card on the one of the drive

shield or on scope's pier.

9. Fit the dome's driving motor on the drive shield

opposite to ScopeDome Card.

10. Connect all elements and wiring according to the

electrical diagram of the observatory.

11. Test driving motors and end switches.

12. Install control software and calibrate the dome.

(Calibration description in Help menu).

Limit switches control wiring and illumination wiring can

be lead through the holes previously drilled in the side

reinforcements close by shutter window.

EN