Page 18

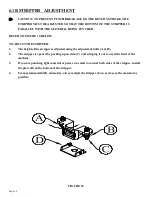

The stroke setting is important for the proper operation of the machine. If this setting has changed,

the machine may over-travel and cause the cylinder to "bottom out". This continued condition will

eventually cause the starter overload to open. It can also cause the hydraulic oil to overheat and damage

hydraulic system components. A slight change in the stroke setting can result in inadequate stroke to

operate the tooling.

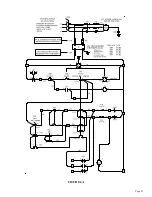

A check of the machine’s stroke setting is made at the punch station; SEE FIGURE 5 ON THE

FOLLOWING PAGE. Set the stroke control handles (A) out to their farthest position. Turn the

selector switch (G) to the START position and power the machine. Then place this switch in the

SHEAR position. Measure the distance from the top of the punch bolster to the bottom of the punch

ram. The distance should be 9-1/32 inches (229mm). Turn the selector switch to the PUNCH position

and measure the distance. The distance should be 6-25/32 inches (172mm).

These dimensions are are + or - 1/16 of

an inch (3mm).

IF THE STROKE IS OUT OF THESE LIMITS, THEN USE THE FOLLOWING PROCEDURE:

1.

Loosen the two mounting plate screws (D) that hold the mounting plate to the machine.

SEE FIGURE 5 ON THE FOLLOWING PAGE.

2.

Move the plate vertically, up or down. Moving the plate up will bring the distance down and a

movement down will bring the distance up.

3.

Tighten the screws and re-check the dimensions. Repeat, if needed.

A.

STROKE CONTROL HANDLES

B.

SCALE - STROKE CONTROL

C.

METERING BOSS

D.

MOUNTING PLATE SCREWS

E.

JOG CONTROL

F.

JOG/RUN/PROBE SWITCH

G.

PUNCH/START/SHEAR SWITCH

H.

EMERGENCY STOP SWITCH

I.

START BUTTON

4.6 MACHINE STROKE INSPECTION & ADJUSTMENT

Summary of Contents for 9012-24M

Page 10: ...Page 9 FIGURE 1 ...

Page 12: ...Page 11 FIGURE 2 ...

Page 16: ...Page 15 FIGURE 4A ...

Page 17: ...Page 16 FIGURE 4B ...

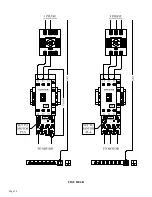

Page 18: ...Page 17 FIGURE 4C ...

Page 22: ...Page 21 FIGURE 6 ...

Page 24: ...Page 23 FIGURE 7 ...

Page 35: ...Page 34 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 40: ...Page 39 FIGURE 15 ...

Page 42: ...Page 41 FIGURE 16 ...

Page 48: ...Page 47 FIGURE 20 ...

Page 54: ...Page 53 FIGURE 24 ...

Page 56: ...Page 55 FIGURE 25 ...

Page 62: ...Page 61 FIGURE 27 ...

Page 66: ...Page 65 FIGURE 29 ...

Page 68: ...Page 67 FIGURE 30 ...

Page 74: ...Page 73 FIGURE 32 ...

Page 78: ...Page 77 FIGURE 34 ...

Page 80: ...Page 79 FIGURE 35 ...

Page 82: ...Page 81 FIGURE 36 ...

Page 84: ...Page 83 FIGURE 37 ...

Page 86: ...Page 85 FIGURE 38 ...

Page 90: ...Page 89 FIGURE 41 ...

Page 92: ...Page 91 FIGURE 42 ...

Page 93: ...Page 92 FIGURE 43 ...

Page 96: ...Page 95 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 98: ...Page 97 FIGURE 46 ...

Page 100: ...Page 99 FIGURE 47 ...