8.4 SETTING BELT TENSION

SEE FIGURE 21 BELOW

After changing the roller the belt can be installed. Slide the grinding belt over the drive pulley and the

grinding roller. Make sure it is installed so it rotates in the right direction as shown in Sect. 8.1

NOTE: If a roller smaller than 30mm (1-3/16") diameter is being used, use a grinding belt that has

been "broken in" meaning a belt that has been previously used on a roller with a larger diameter. A

new grinding belt is very stiff and may break if used on a grinding roller with a small diameter.

After installing the new grinding belt, the notcher roller support must be reattached via the (2)

wing-nut fasteners. See FIGURE 18

The belt must be tensioned properly. Turn the hand wheel to tighten the belt. To set the correct tension,

use the "Tension Gauge" located on top of the machine. It's on the motor side and directly above the

motor. the spring on the tensioning device should be compressed enough so there is a 8-10mm gap

(.5/16 - .3/8") between the two white indicators as shown below in FIGURE 21.

8-10mm GAP

(5/16"-3/8")

CORRECT

TENSION

FIGURE 21

PAGE 35

Summary of Contents for AL150-HS

Page 2: ...PAGE 2 MODEL AL150 HS HIGH SPEED PIPE NOTCHER GRINDER...

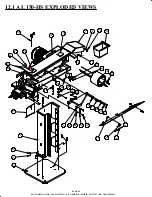

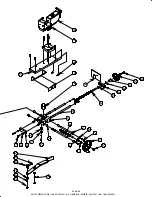

Page 11: ...6 2 3 5 7 8 FIGURE 2 4 1 PAGE 11...

Page 19: ...PAGE 19 COVER SWITCH PLUNGER COVER SWITCH PUSHER HINGED COVER FIGURE 8 REAR COVER SWITCH...

Page 21: ...FIGURE 9 MODEL AL 150 HS 1 2 3 4 5 6 7 8 PAGE 21 9 ITEM 7 DETAIL CONTROLS ADJUSTMENTS...