8.5 SETTING BELT TRACKING

After changing the roller and belt and tensioning it properly, The next thing is to check the tracking of

the belt. You want the belt to run so it's as centered on the rollers as it can be.

To begin, make sure the machine is still DISCONNECTED FROM POWER.

Slowly roll the belt by hand in the right direction and see how it tracks. If it rubs on either side, adjust

the tracking while rolling the belt by hand. Once belt is centered, roll it by hand for several revolutions.

If it stays on the rollers and is NOT rubbing on either side, go ahead and close ALL the covers making

sure they are properly locked shut. Make sure the clear cover on the notcher end of the machine is

flipped down & deburring cover is closed.

Connect the power to the machine.

NOTE: Make sure you are wearing the proper safety equipment!!

At this point we're ready to start the machine. Be prepared to stop the machine in case any difficulties

are encountered.

Once the machine is started and running, check the belt to see how it's tracking by watching the front

roller. If it tracking off to one side or the other use the 8mm Allen key to slowly adjust the tracking.

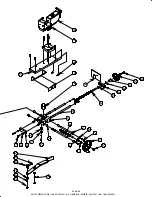

SEE FIGURE 22

Below shows where the tracking adjustment is made. There is a hole in the side-cover of the machine

that allows access to the adjustment bolt.

CAUTION: Turn Tracking Adjustment Bolt Slowly!!

Watch the grinding belt closely while turning the tracking adjustment bolt.

Once the belt is centered and tracking good, let the machine run for a minute to make sure it stays.

Machine is now ready for use.

TRACKING ADJUSTMENT

PAGE 36

FIGURE 22

Summary of Contents for AL150-HS

Page 2: ...PAGE 2 MODEL AL150 HS HIGH SPEED PIPE NOTCHER GRINDER...

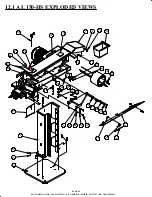

Page 11: ...6 2 3 5 7 8 FIGURE 2 4 1 PAGE 11...

Page 19: ...PAGE 19 COVER SWITCH PLUNGER COVER SWITCH PUSHER HINGED COVER FIGURE 8 REAR COVER SWITCH...

Page 21: ...FIGURE 9 MODEL AL 150 HS 1 2 3 4 5 6 7 8 PAGE 21 9 ITEM 7 DETAIL CONTROLS ADJUSTMENTS...