1.0 INTRODUCTION

Tube & Pipe Notch Grinders

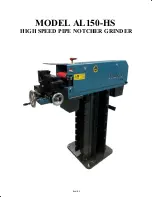

Scotchman Tube & Pipe Grinder/Notchers are strong, accurate machines. The AL150-HS operates at a

higher speed than our other grinders and grinds a notch much faster. Stainless-steel sections and pipes

can be machined problem free, at high speed without grinding burrs or heat discoloration. The

grinding rollers can be changed without tools in just seconds, saving time and money! The grinding

belt can also be changed easily from one side of the machine. Once the sections and pipes have been

ground, they can be deburred using the high speed parts grinder on the other end of the machine.

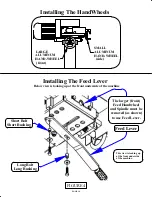

The AL150-HS can feed the tube with either a handwheel or a lever. The pipe grinder/notchers offer

trouble-free, accurate, quick and efficient machining of tubes and pipes for many years; and are

backed by a 3-year warranty.

FEATURES:

Fast, strong and accurate

Ideally suited for grinding stainless quickly

Fitted with grinding rollers that can be changed in seconds

Equipped with a high speed parts grinder

Tool Free Belt and Mandrel Change Over

Grinds tube and pipe at every angle between 30 degrees and 90 degrees

3-Year Warranty

2.0 SAFETY PRECAUTIONS

1.

The operators of this machine must be qualified and well trained in the operation of the machine.

The operators must be aware of the capacities of the machine and the proper use of the holding

device and the guards provided with the machine. This manual is not intended to teach untrained

personnel how to operate machinery.

2.

All of the guards, and awareness barriers must be installed on the machine and kept in good

working order. Promptly replace worn or damaged parts with the correct authorized parts.

3.

Never place any part of your body into any of the machine’s moving parts or hold devices.

4.

Wear the appropriate personal protective equipment. This machine grinds metal and creates

abrasive and metallic particles so Safety Glasses are required at all times!! Whether operating,

setting up or observing this machine in operation, Safety Glasses are a requirement.

5. Since pieces of metal with sharp edges are processed on this machine, the operator should also

wear steel-toed shoes and leather gloves.

6.

Strictly comply with all warning labels and decals on the machine. Never remove any of the labels

and replace worn or damaged labels promptly.

7.

Always disconnect and lock out the power when performing maintenance work or repairs on this

machine.

8.

Replace sanding belt when needed. Never operate this machine with a sanding belt that is worn out.

The excessive pressure required to notch a tube with a worn out sanding belt can damage roller and

cut the sanding belt.

PAGE 6

Summary of Contents for AL150-HS

Page 2: ...PAGE 2 MODEL AL150 HS HIGH SPEED PIPE NOTCHER GRINDER...

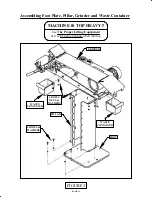

Page 11: ...6 2 3 5 7 8 FIGURE 2 4 1 PAGE 11...

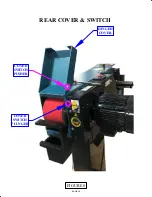

Page 19: ...PAGE 19 COVER SWITCH PLUNGER COVER SWITCH PUSHER HINGED COVER FIGURE 8 REAR COVER SWITCH...

Page 21: ...FIGURE 9 MODEL AL 150 HS 1 2 3 4 5 6 7 8 PAGE 21 9 ITEM 7 DETAIL CONTROLS ADJUSTMENTS...