DWN. BY:

CHK. BY:

Scotchman Inds.

PART NO.

.0 = +/-.02 (.5mm)

.00 = +/-.01 (.25mm)

.000 = +/-.005 (.125mm)

Fractions = +/- 1/32 (.7mm)

Angles = +/- 1'

DATE:

SCALE:

PART NAME:

MATERIAL:

TOLERANCE (UNLESS SPECIFIED)

5/12/16

Jason S.

None

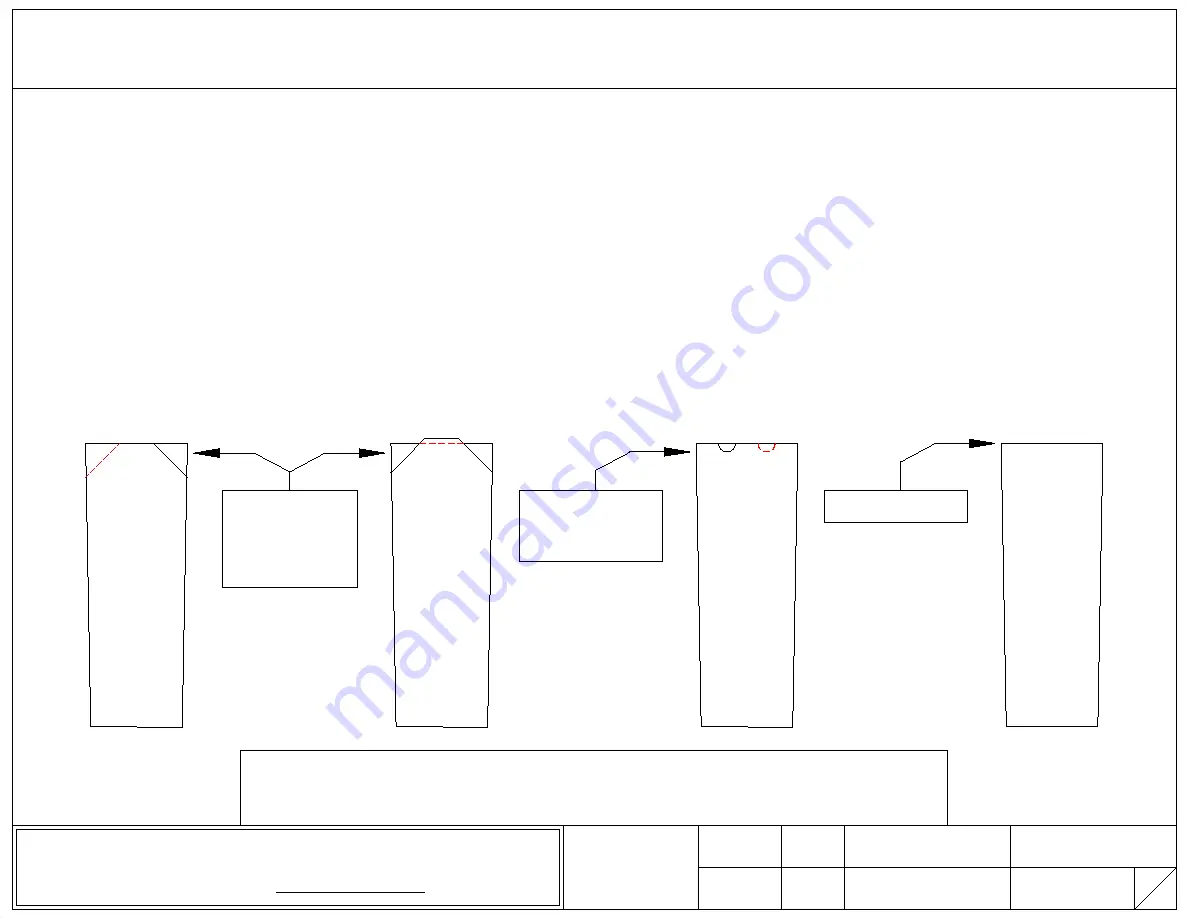

Cold Saw Blade

Selecting the Proper

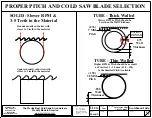

ALTERNATE

Teeth are the same Height.

All the Teeth have a Bevel.

Every Other Tooth is Beveled

on Every Other Side. Used on

Blades with a 4.5 Pitch or Less,

Generally, 220 Teeth or more.

More Teeth = Smaller Pitch

Used on thinner walled Tube &

Angle and Small Solids.

TRIPLE CHIP

Every other Tooth is Taller.

Often said to have a "High-Low".

The High-Tooth has a Bevel on Both

Sides. The Low Tooth has

NO Bevel at all. Hi-Tooth cuts the

Middle out of the Cut and Low

Tooth is the Tooth that leaves Finish.

Generally used on Blades

with a 4.5 Pitch or more.

Less Teeth = Larger Pitch.

Best for Solids and Thick Wall Tube.

NOTCH GRIND

Teeth are the same Height.

All the Teeth have a Notch.

Notches are Offset from Each

Other and breaks up the Chip

made during the Cut. Typically

used on Blades with a 4.5 Pitch or

Less, Generally, 220 Teeth or more.

More Teeth = Smaller Pitch

Best for thinner walled Tube &

Blade RPM should be increased.

ROUND GRIND

Teeth are the same Height.

There is No Bevel. Typically used

on Blades with a 3.5 Pitch or Less,

as Teeth this small are extremely

difficult to bevel. This works best

for thinner walled Tube .

Also used for soft materials such as

Nylon, Plastic, PVC, etc. in most

any shape or size and with

whatever tooth size works the best.

Bevel at 45° Angle

Removes 1/3 of the

"Tip of the Tooth"

Where the cutting

takes place.

3

3

Notches are Off-Set

Breaks up the chip

made during the cut

No Bevel or Notch

TYPES OF BEVELS, NOTCHES, AND WHERE USED

Power 2000 Blades have the Notch Grind & Titanium Coating.

Triple Chip and Alternate Grinds are by far the most common.

The Worlds Best Cold Saws & Ironworkers

Proudly Made In America

www.scotchman.com

Scotchman Inds.

180 E US Hwy 14

Philip, SD 57567

1-605-859-2542

info@scotchman.com

Summary of Contents for CPO-275

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 13: ...Page 12 MANUAL OR PK W TRIGGER SWITCH FIGURE 3 1...

Page 14: ...Page 13 PKPD W EMERGENCY STOP FIGURE 3 2...

Page 15: ...Page 14 1 PHASE MOTOR W TRIGGER SWITCH FIGURE 3 3...

Page 16: ...Page 15 1 PHASE MOTOR W E STOP SERIAL S B3431 UP FIGURE 3 4...

Page 22: ...Page 21 FIGURE 5A...

Page 28: ...Page 27 FIGURE 8 FIGURE 9...

Page 30: ...Page 29 FIGURE 10...

Page 36: ...FIGURE 14 Page 35 C A B D...

Page 38: ...Page 37 FIGURE 15...

Page 40: ...Page 39 FIGURE 16...

Page 42: ...Page 41 FIGURE 17...

Page 44: ...Page 43 FIGURE 18...

Page 46: ...Page 45 FIGURE 19...

Page 48: ...Page 47 FIGURE 20...

Page 50: ...Page 49 FIGURE 20A...

Page 58: ...Page 57 FIGURE 23...

Page 60: ...FIGURE 24 Page 59...

Page 62: ...Page 61 G 078000 60 RPM 230 Volt 1 Phase T S 078001 60 RPM 230 Volt 1 Phase E S FIGURE 25...

Page 66: ...Page 65 FIGURE 27...

Page 68: ...Page 67 FIGURE 28...

Page 70: ...Page 69 FIGURE 29...

Page 74: ...Page 73 FIGURE 31...

Page 76: ...Page 75 FIGURE 32...

Page 78: ...Page 77 FIGURE 33...

Page 80: ...FIGURE 34 Page 79...

Page 82: ...Page 81 FIGURE 35...

Page 84: ...Page 83 FIGURE 36...

Page 86: ...Page 85 FIGURE 37...

Page 88: ...Page 87 FIGURE 38...

Page 90: ...Page 89 FIGURE 39...