Page 16

4.5 MACHINE START-UP

Before starting this machine, take the time to review the operator’s manual thoroughly, to familiarize

yourself with all of the functions of the machine.

We strongly urge you to follow OSHA directive CFR-1910.147 (effective 09-09-90) regarding lock-out,

tag-out procedures. Keep in mind that the directive refers to all hazardous energy sources, not just

electrical.

On machines equipped with either a power vise or a power down feed, the air supply must also be

disconnected and locked or tagged. If your plant is not equipped with lock-out capabilities, Scotchman

offers a lock-out switch as an option for this machine. If you are interested in this option, REFER TO

SECTION 7.6 or contact your local dealer or the factory.

Do not install a blade on the saw until after it has been powered and cycled several times. To power

manual and power vise machines, turn the HI-LOW switch to either the HI or LOW position and

use the trigger switch mounted in the draw handle to start the motor. Always turn the HI-LOW switch

to the OFF position when the saw is not in use.

On machines equipped with a 1-phase motor, use the trigger switch to start the motor.

To power machines equipped with the power down feed option, turn the HI-LOW switch to either the HI

or LOW position and depress the foot switch to start the blade.

You must use the emergency stop switch to turn off the coolant pump. When the emergency stop switch is

used, it must be manually reset by pulling the switch back out.

Always turn the HI-LOW switch to the OFF position when the saw is not in use.

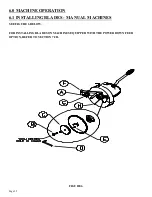

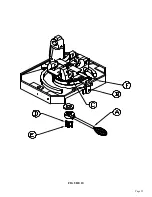

Once the machine has been powered, check the rotation of the spindle. There is an arrow on the guard

showing the proper rotation. If the rotation is not correct, the electrician will have to switch two of the

three line wires.

Check the rotation of the coolant pump, also. There is an arrow cast in the top of the pump.

If the saw is equipped with either the power vise or the power down feed options, SEE SECTIONS 7.1

THRU 7.2, for additional information on electrical and air connections.

Summary of Contents for CPO-275

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

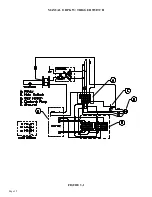

Page 13: ...Page 12 MANUAL OR PK W TRIGGER SWITCH FIGURE 3 1...

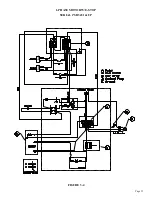

Page 14: ...Page 13 PKPD W EMERGENCY STOP FIGURE 3 2...

Page 15: ...Page 14 1 PHASE MOTOR W TRIGGER SWITCH FIGURE 3 3...

Page 16: ...Page 15 1 PHASE MOTOR W E STOP SERIAL S B3431 UP FIGURE 3 4...

Page 22: ...Page 21 FIGURE 5A...

Page 28: ...Page 27 FIGURE 8 FIGURE 9...

Page 30: ...Page 29 FIGURE 10...

Page 36: ...FIGURE 14 Page 35 C A B D...

Page 38: ...Page 37 FIGURE 15...

Page 40: ...Page 39 FIGURE 16...

Page 42: ...Page 41 FIGURE 17...

Page 44: ...Page 43 FIGURE 18...

Page 46: ...Page 45 FIGURE 19...

Page 48: ...Page 47 FIGURE 20...

Page 50: ...Page 49 FIGURE 20A...

Page 58: ...Page 57 FIGURE 23...

Page 60: ...FIGURE 24 Page 59...

Page 62: ...Page 61 G 078000 60 RPM 230 Volt 1 Phase T S 078001 60 RPM 230 Volt 1 Phase E S FIGURE 25...

Page 66: ...Page 65 FIGURE 27...

Page 68: ...Page 67 FIGURE 28...

Page 70: ...Page 69 FIGURE 29...

Page 74: ...Page 73 FIGURE 31...

Page 76: ...Page 75 FIGURE 32...

Page 78: ...Page 77 FIGURE 33...

Page 80: ...FIGURE 34 Page 79...

Page 82: ...Page 81 FIGURE 35...

Page 84: ...Page 83 FIGURE 36...

Page 86: ...Page 85 FIGURE 37...

Page 88: ...Page 87 FIGURE 38...

Page 90: ...Page 89 FIGURE 39...