4.7 COOLANT SYSTEM

5.0 MAINTENANCE AND LUBRICATION

5.1 LUBRICATION

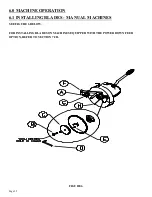

SEE FIGURE 5 BELOW.

Before operating the saw, grease the pivot pin (A) and apply penetrating oil to the vise spindle and

guides (B and C). Once a week, grease all of the pivot pins and oil all of the rivet connections on the

guard linkage (D). Clean the chips out of the vise at least once a day and apply penetrating oil to the

spindle and guide pins. Clear the chips with a brush or similar device. DO NOT use compressed air.

If your saw is equipped with a power vise or power down feed option, SEE SECTIONS 7.1 THRU 7.2,

for additional information.

FIGURE 5

Page 18

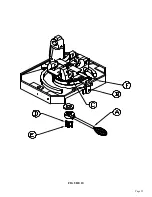

The coolant reservoir has a capacity of eight (8) gallons (30.3 liters). One gallon of coolant is shipped

with the saw. For normal cutting, it should be mixed in a ratio of one part coolant to seven parts water.

In conditions of heavier cutting, the ratio of water should be reduced to five parts. We recommend

using only pure, synthetic, water soluble cutting oils. There is a sieve screen in the back of the cast vise

base. To aid in adding coolant, the sieve screen can be removed with a screwdriver. Do not remove the

sieve screen if the base of the saw is not completely clean and free of chips. The plastic panel on the

back of the machine base can also be removed, to aid in adding coolant. We recommend pre-mixing

the coolant before adding it to the saw. When cutting alloy steels such as stainless steel, we recommend

a special mix coolant designed for these applications. For additional information on available coolants,

SEE SECTION 10.5.

D

B & C

A

Summary of Contents for CPO-275

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 13: ...Page 12 MANUAL OR PK W TRIGGER SWITCH FIGURE 3 1...

Page 14: ...Page 13 PKPD W EMERGENCY STOP FIGURE 3 2...

Page 15: ...Page 14 1 PHASE MOTOR W TRIGGER SWITCH FIGURE 3 3...

Page 16: ...Page 15 1 PHASE MOTOR W E STOP SERIAL S B3431 UP FIGURE 3 4...

Page 22: ...Page 21 FIGURE 5A...

Page 28: ...Page 27 FIGURE 8 FIGURE 9...

Page 30: ...Page 29 FIGURE 10...

Page 36: ...FIGURE 14 Page 35 C A B D...

Page 38: ...Page 37 FIGURE 15...

Page 40: ...Page 39 FIGURE 16...

Page 42: ...Page 41 FIGURE 17...

Page 44: ...Page 43 FIGURE 18...

Page 46: ...Page 45 FIGURE 19...

Page 48: ...Page 47 FIGURE 20...

Page 50: ...Page 49 FIGURE 20A...

Page 58: ...Page 57 FIGURE 23...

Page 60: ...FIGURE 24 Page 59...

Page 62: ...Page 61 G 078000 60 RPM 230 Volt 1 Phase T S 078001 60 RPM 230 Volt 1 Phase E S FIGURE 25...

Page 66: ...Page 65 FIGURE 27...

Page 68: ...Page 67 FIGURE 28...

Page 70: ...Page 69 FIGURE 29...

Page 74: ...Page 73 FIGURE 31...

Page 76: ...Page 75 FIGURE 32...

Page 78: ...Page 77 FIGURE 33...

Page 80: ...FIGURE 34 Page 79...

Page 82: ...Page 81 FIGURE 35...

Page 84: ...Page 83 FIGURE 36...

Page 86: ...Page 85 FIGURE 37...

Page 88: ...Page 87 FIGURE 38...

Page 90: ...Page 89 FIGURE 39...