Page 26

6.4 MATERIAL CLAMPING

All work pieces must be clamped securely in the vise. Any slippage of the material can result in broken

or damaged blades. The material should be clamped so that the contact surface between the material

and the blade is as small as possible. For this reason, when cutting flat stock material, we recommend

standing it up and cutting it through the thinnest section, whenever possible.

If the flat stock is too wide to clamp standing up, clamp it in the vise diagonally. We also recommend

cutting square tubing through the diagonal section and angle iron with the web up. For examples,

SEE FIGURE 8 ON THE FOLLOWING PAGE. This is not always possible when cutting materials

at a miter. Some thin walled round sections and profiles will require special jaws to hold them. When

trimming or cutting very short pieces that do not extend into both sides of the vise, place a piece of

material the same size in the unused side of the vise, to insure uniform clamping. When setting up the

saw to miter cut, pull the head down before making the first cut, to make sure that the blade clears the

vise jaws.

The steel jaws have slotted mounting holes and can be adjusted for various miters. Always adjust the

steel jaws so that they clamp the material as close to the blade as possible, whether miter or straight

cutting. All models of the CPO-350, except those fitted with the power down feed option, have a down

stroke or cutting depth adjustment. SEE FIGURE 9 ON THE FOLLOWING PAGE. This adjustment

is used to keep the saw blade from cutting into the vise spindle and must be adjusted when changing sizes

of materials or blades. If your saw is equipped with either the power vise or the power down feed options,

SEE SECTIONS 7.1 THRU 7.2, for additional information.

Summary of Contents for CPO-275

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

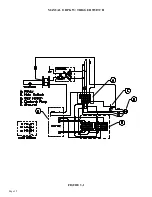

Page 13: ...Page 12 MANUAL OR PK W TRIGGER SWITCH FIGURE 3 1...

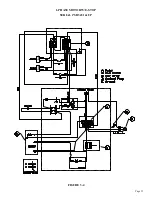

Page 14: ...Page 13 PKPD W EMERGENCY STOP FIGURE 3 2...

Page 15: ...Page 14 1 PHASE MOTOR W TRIGGER SWITCH FIGURE 3 3...

Page 16: ...Page 15 1 PHASE MOTOR W E STOP SERIAL S B3431 UP FIGURE 3 4...

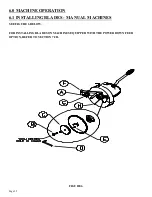

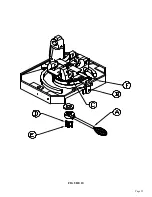

Page 22: ...Page 21 FIGURE 5A...

Page 28: ...Page 27 FIGURE 8 FIGURE 9...

Page 30: ...Page 29 FIGURE 10...

Page 36: ...FIGURE 14 Page 35 C A B D...

Page 38: ...Page 37 FIGURE 15...

Page 40: ...Page 39 FIGURE 16...

Page 42: ...Page 41 FIGURE 17...

Page 44: ...Page 43 FIGURE 18...

Page 46: ...Page 45 FIGURE 19...

Page 48: ...Page 47 FIGURE 20...

Page 50: ...Page 49 FIGURE 20A...

Page 58: ...Page 57 FIGURE 23...

Page 60: ...FIGURE 24 Page 59...

Page 62: ...Page 61 G 078000 60 RPM 230 Volt 1 Phase T S 078001 60 RPM 230 Volt 1 Phase E S FIGURE 25...

Page 66: ...Page 65 FIGURE 27...

Page 68: ...Page 67 FIGURE 28...

Page 70: ...Page 69 FIGURE 29...

Page 74: ...Page 73 FIGURE 31...

Page 76: ...Page 75 FIGURE 32...

Page 78: ...Page 77 FIGURE 33...

Page 80: ...FIGURE 34 Page 79...

Page 82: ...Page 81 FIGURE 35...

Page 84: ...Page 83 FIGURE 36...

Page 86: ...Page 85 FIGURE 37...

Page 88: ...Page 87 FIGURE 38...

Page 90: ...Page 89 FIGURE 39...