Page 40

7.2D INSTALLING BLADES (POWER DOWN FEED)

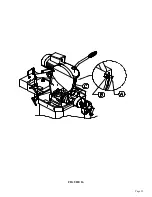

SEE FIGURE 17 ON THE FOLLOWING PAGE.

⌦

CAUTION: USE ONLY HIGH SPEED STEEL BLADES DESIGNED FOR THIS MACHINE.

DO NOT MODIFY ANY BLADE TO FIT THIS MACHINE. DO NOT USE BLADES

DESIGNED FOR THIS MACHINE ON ANY OTHER EQUIPMENT.

The CPO-350 saw is designed to use a maximum 14 inch (350mm) diameter blade. The arbor size is

40mm with four 12mm pins spaced at 64mm.

BEFORE INSTALLING THE BLADE, make sure that the power to the machine is disconnected.

USE THE FOLLOWING STEPS TO INSTALL A BLADE:

(An 8mm hex key wrench (A), shipped with each machine, is required to change blades.)

1.

Release the upper stroke control and allow the head to travel to its full UP position.

2.

Raise the movable section of the guard (B) to the OPEN position.

3.

Remove the blade bolt (C) through the center hole in the blade guard.

4.

Remove the blade flange (D).

5.

Install the blade. Make sure that the pin holes line up to the holes in the spindle.

6.

Replace the blade flange and start the bolt into the spindle.

7.

Before locking the blade in position, the back lash must be taken up. To take up the back lash,

rotate the bottom of the blade toward you until it seats against the drive pins.

⌦

CAUTION: THE BLADES ARE VERY SHARP AND CARE MUST BE TAKEN WHEN

REMOVING THE BACK LASH. DO NOT GRIP THE CUTTING EDGE OF THE BLADE

BARE HANDED. THE BACK LASH MUST BE TAKEN UP EVERY TIME A BLADE IS

CHANGED.

8.

After taking up the back lash, tighten the blade bolt (C).

9.

Return the movable guard to the DOWN position and re-set the upper stroke control.

10.

Break in the saw blade. The teeth on new or re-sharpened blades have a sharp edge and should be

fed through the first three or four cuts, very slowly, before starting normal cutting. Besides taking

up the back lash and breaking in the blade, it is very important to keep the blade flange, the

spindle and the blade clean and free from nicks. Failure to do these things will result in broken or

damaged blades.

Summary of Contents for CPO-275

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 13: ...Page 12 MANUAL OR PK W TRIGGER SWITCH FIGURE 3 1...

Page 14: ...Page 13 PKPD W EMERGENCY STOP FIGURE 3 2...

Page 15: ...Page 14 1 PHASE MOTOR W TRIGGER SWITCH FIGURE 3 3...

Page 16: ...Page 15 1 PHASE MOTOR W E STOP SERIAL S B3431 UP FIGURE 3 4...

Page 22: ...Page 21 FIGURE 5A...

Page 28: ...Page 27 FIGURE 8 FIGURE 9...

Page 30: ...Page 29 FIGURE 10...

Page 36: ...FIGURE 14 Page 35 C A B D...

Page 38: ...Page 37 FIGURE 15...

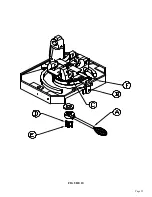

Page 40: ...Page 39 FIGURE 16...

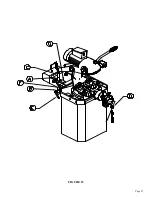

Page 42: ...Page 41 FIGURE 17...

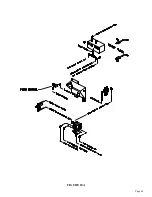

Page 44: ...Page 43 FIGURE 18...

Page 46: ...Page 45 FIGURE 19...

Page 48: ...Page 47 FIGURE 20...

Page 50: ...Page 49 FIGURE 20A...

Page 58: ...Page 57 FIGURE 23...

Page 60: ...FIGURE 24 Page 59...

Page 62: ...Page 61 G 078000 60 RPM 230 Volt 1 Phase T S 078001 60 RPM 230 Volt 1 Phase E S FIGURE 25...

Page 66: ...Page 65 FIGURE 27...

Page 68: ...Page 67 FIGURE 28...

Page 70: ...Page 69 FIGURE 29...

Page 74: ...Page 73 FIGURE 31...

Page 76: ...Page 75 FIGURE 32...

Page 78: ...Page 77 FIGURE 33...

Page 80: ...FIGURE 34 Page 79...

Page 82: ...Page 81 FIGURE 35...

Page 84: ...Page 83 FIGURE 36...

Page 86: ...Page 85 FIGURE 37...

Page 88: ...Page 87 FIGURE 38...

Page 90: ...Page 89 FIGURE 39...