10.5 COOLANTS AND LUBRICANTS

PART #

1 Gal.

5 Gal.

55 Gal.

1 Gal.

5 Gal.

1 Qt.

1 Gal.

075751

075752

075754

075756

075757

075753

075759

DESCRIPTION

Synthetic Coolant

Synthetic Coolant

Synthetic Coolant

Special Mix Coolant

Special Mix Coolant

Air Line Lubricant

Air Line Lubricant

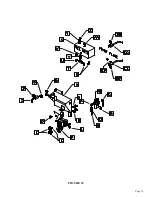

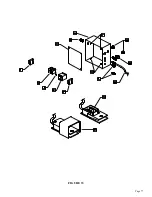

10.6 LOCK-OUT/DISCONNECT SWITCH

ITEM

PART #

A

B

C

D

E

F

G

H

563025

562250

N/A

563441

108010

158200

224205

114010

078200

Page 84

DESCRIPTION

Disconnect Switch

Mounting Plate

Cord

Cord Connector

1/4" Hex Nut

Grommet

M-10 WLCS

1/4" Washer

Disconnect Ass’y (A, D, E, F)

1 Gal.

075758

Gear Oil - Head

ITEM

Summary of Contents for CPO-275

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 13: ...Page 12 MANUAL OR PK W TRIGGER SWITCH FIGURE 3 1...

Page 14: ...Page 13 PKPD W EMERGENCY STOP FIGURE 3 2...

Page 15: ...Page 14 1 PHASE MOTOR W TRIGGER SWITCH FIGURE 3 3...

Page 16: ...Page 15 1 PHASE MOTOR W E STOP SERIAL S B3431 UP FIGURE 3 4...

Page 22: ...Page 21 FIGURE 5A...

Page 28: ...Page 27 FIGURE 8 FIGURE 9...

Page 30: ...Page 29 FIGURE 10...

Page 36: ...FIGURE 14 Page 35 C A B D...

Page 38: ...Page 37 FIGURE 15...

Page 40: ...Page 39 FIGURE 16...

Page 42: ...Page 41 FIGURE 17...

Page 44: ...Page 43 FIGURE 18...

Page 46: ...Page 45 FIGURE 19...

Page 48: ...Page 47 FIGURE 20...

Page 50: ...Page 49 FIGURE 20A...

Page 58: ...Page 57 FIGURE 23...

Page 60: ...FIGURE 24 Page 59...

Page 62: ...Page 61 G 078000 60 RPM 230 Volt 1 Phase T S 078001 60 RPM 230 Volt 1 Phase E S FIGURE 25...

Page 66: ...Page 65 FIGURE 27...

Page 68: ...Page 67 FIGURE 28...

Page 70: ...Page 69 FIGURE 29...

Page 74: ...Page 73 FIGURE 31...

Page 76: ...Page 75 FIGURE 32...

Page 78: ...Page 77 FIGURE 33...

Page 80: ...FIGURE 34 Page 79...

Page 82: ...Page 81 FIGURE 35...

Page 84: ...Page 83 FIGURE 36...

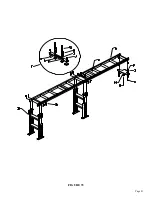

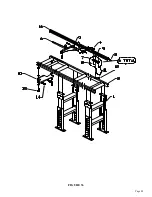

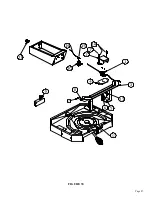

Page 86: ...Page 85 FIGURE 37...

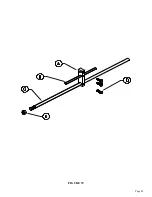

Page 88: ...Page 87 FIGURE 38...

Page 90: ...Page 89 FIGURE 39...