Page 14

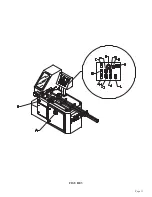

5.1A MAIN POWER SWITCH

This is the main power disconnect switch for the machine and it should be locked or tagged in the OFF

position any time maintenance or service work is being performed. Maintenance or service work on the

electrical controls must be performed by qualified personnel. This switch must be in the ON position to

operate any of the other control panel functions.

There is a red power indicator light on the control panel. This light indicates that this switch is in the

ON position. This switch must be in the ON position when changing the fuses in the PLC. If the

fuses are removed with the power OFF, the PLC memory will be lost.

CAUTION: THIS SWITCH DOES NOT DISCONNECT THE AIR SUPPLY TO THE

MACHINE. ANY TIME MAINTENANCE OR SERVICE WORK IS PERFORMED ON THE

MACHINE, THE AIR SUPPLY MUST ALSO BE DISCONNECTED AND TAGGED OR

LOCKED OUT.

5.1B MOTOR CONTROL SWITCH

This switch is used to turn the motor on.

5. 1C POWER UP SWITCH

This switch energizes the system for the rest of the control panel functions. This switch will also start the

saw motor. The motor will not start unless the MAIN POWER switch (A) is on and the AUTOMATIC/

MANUAL SWITCH (I) is in the MANUAL position. The MOTOR SWITCH (B) must be in the on

position for the saw motor to start.

5.1D EMERGENCY STOP SWITCH

This switch stops the saw motor and allows the head to return to the up position. The emergency stop

switch does not release the material vise or the air pressure. Once this switch has been used, the operator

must restart the machine in the MANUAL position and go through the startup procedure again. For

complete instructions on changing bars of material, REFER TO SECTION 7.0.

5.1E HEAD UP

This button is used to abort a cut in mid cycle when the AUTOMATIC/MANUAL SWITCH is in the

MANUAL position. This button is inoperable when the machine is in the AUTOMATIC position.

Summary of Contents for CPO-315-HFA-NF

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 14: ...Page 13 FIGURE 3...

Page 18: ...Page 17 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 22: ...Page 21 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 23: ...Page 22 6 3 MATERIAL MAIN VISE SEE FIGURE 6 BELOW FIGURE 6...

Page 25: ...Page 24 FIGURE 7...

Page 27: ...Page 26 6 6 POWER DOWN FEED REFER TO FIGURE 8 BELOW FIGURE 8...

Page 30: ...Page 29 FIGURE 9...

Page 31: ...Page 30 6 9 COUNTER SET UP REFER TO FIGURE 10 BELOW FIGURE 10...

Page 33: ...Page 32 7 0 MACHINE AUTOMATIC OPERATION SET UP REFER TO FIGURE 11 BELOW FIGURE 11...

Page 37: ...Page 36 8 4 SPINDLE SHAFT REPLACEMENT REFER TO FIGURE 13 BELOW FIGURE 13...

Page 39: ...Page 38 8 5 SPINDLE REPLACEMENT MAIN VISE SEE FIGURE 14 BELOW FIGURE 14...

Page 41: ...Page 40 8 7 SHUTTLE VISE MAINTENANCE SEE FIGURE 15 BELOW FIGURE 15...

Page 44: ...Page 43 FIGURE 16...

Page 50: ...Page 49 FIGURE 18...

Page 56: ......

Page 60: ...Page 59 FIGURE 23...

Page 62: ...Page 61 FIGURE 24...

Page 64: ...Page 63 FIGURE 25...

Page 66: ...Page 65 FIGURE 26...

Page 68: ...Page 67 FIGURE 27...

Page 70: ...Page 69 FIGURE 28...

Page 72: ...Page 71 FIGURE 29...

Page 75: ......

Page 76: ......

Page 78: ...Page 77 FIGURE 31...

Page 80: ...Page 79 FIGURE 32...

Page 82: ...Page 81 FIGURE 33...

Page 84: ...Page 83 FIGURE 34...

Page 86: ...Page 85 FIGURE 35...

Page 88: ...Page 87 FIGURE 36...

Page 90: ...Page 89 FIGURE 37...

Page 92: ...14 0 WIRING DIAGRAMS Page 91 045345 Scotchman Inds PART NO...

Page 93: ...3 5PB 1PL 045345 Scotchman Inds PART NO 1 3 Page 92 Ser s B1392HFANF0314 Up Part of Next Page...