Page 33

The following instructions are to set up a job for automatic operation. Make sure that you are familiar

with the functions of all of the switches and buttons before proceeding.

1.

Set the shuttle vise indicator to the desired length by loosening the moving stop (M) and then,

move it to the length desired on the scale and re-tighten it.

2.

Place the HITCH FEED switch (G) in the desired position.

3.

Adjust the shuttle vise and material vise for the size of material. Adjust the vises up to the

material, allowing approximately 1/8 of an inch (3mm) clearance for the throw of the cylinder.

4.

Set the upper and lower stroke of the saw head. For instructions, REFER TO SECTION 6.8.

5.

Place the main power switch (A) in the ON position and the motor control switch (B) in the ON

position.

6.

Place the AUTO/MANUAL switch (I) in the MANUAL position and then, pull the EMERGENCY

STOP switch (D) out.

7.

Place the material to be cut in the material vise jaws so that 1/4 to 1/2 inch extends past the blade

slot.

8.

Press the POWER UP button (C).

9.

Press the TRIM/TEST button (J) and the CYCLE button (H). The machine will make a trim and

a test cut. Adjust the down feed rate of the head, using the flow control valve (N), while it is

making the first cut.

10.

Check the accuracy of the first part and make any adjustments required. The fine adjustment

knob (O) will change the length of the part by 1.5 thousandths of an inch per increment.

11.

Press the CYCLE button again and the machine will make another test cut.

12.

Set the counter (P) to the desired number of pieces. For instructions, REFER TO SECTION 6.9.

13.

After you have made all of the fine adjustments, place the AUTO/MANUAL switch in the AUTO

position and press the CYCLE button again. The machine will start the automatic operation and

continue until the counter reaches the set quantity or the machine runs out of material.

IMPORTANT: WHEN THE MACHINE HAS FINISHED A BAR OF MATERIAL, YOU HAVE

TO RESET THE MACHINE BEFORE CONTINUING WITH THE AUTOMATIC

OPERATION.

TO RESET THE MACHINE:

1.

Load the new bar in the machine with approximately 1/2 inch extending past the blade slot in the

material vise.

2.

Turn the AUTOMATIC/MANUAL switch (I) to the MANUAL position.

3.

Push the TRIM/TEST button (J) and then, the CYCLE button (H). The saw will make one trim

cut and one test cut.

4.

Place the AUTOMATIC/MANUAL switch (I) in the AUTOMATIC position and press the

CYCLE button (H) and the saw will continue with the automatic operation.

CAUTION: FAILURE TO FOLLOW THE ABOVE PROCEDURE EVERY TIME A NEW BAR

IS LOADED WILL CAUSE THE MACHINE TO MALFUNCTION.

Summary of Contents for CPO-315-HFA-NF

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 14: ...Page 13 FIGURE 3...

Page 18: ...Page 17 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 22: ...Page 21 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 23: ...Page 22 6 3 MATERIAL MAIN VISE SEE FIGURE 6 BELOW FIGURE 6...

Page 25: ...Page 24 FIGURE 7...

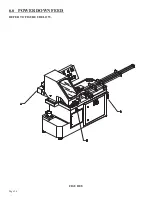

Page 27: ...Page 26 6 6 POWER DOWN FEED REFER TO FIGURE 8 BELOW FIGURE 8...

Page 30: ...Page 29 FIGURE 9...

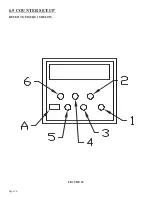

Page 31: ...Page 30 6 9 COUNTER SET UP REFER TO FIGURE 10 BELOW FIGURE 10...

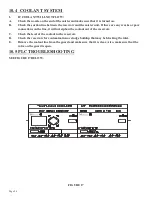

Page 33: ...Page 32 7 0 MACHINE AUTOMATIC OPERATION SET UP REFER TO FIGURE 11 BELOW FIGURE 11...

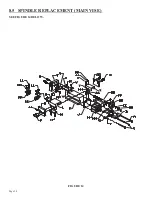

Page 37: ...Page 36 8 4 SPINDLE SHAFT REPLACEMENT REFER TO FIGURE 13 BELOW FIGURE 13...

Page 39: ...Page 38 8 5 SPINDLE REPLACEMENT MAIN VISE SEE FIGURE 14 BELOW FIGURE 14...

Page 41: ...Page 40 8 7 SHUTTLE VISE MAINTENANCE SEE FIGURE 15 BELOW FIGURE 15...

Page 44: ...Page 43 FIGURE 16...

Page 50: ...Page 49 FIGURE 18...

Page 56: ......

Page 60: ...Page 59 FIGURE 23...

Page 62: ...Page 61 FIGURE 24...

Page 64: ...Page 63 FIGURE 25...

Page 66: ...Page 65 FIGURE 26...

Page 68: ...Page 67 FIGURE 27...

Page 70: ...Page 69 FIGURE 28...

Page 72: ...Page 71 FIGURE 29...

Page 75: ......

Page 76: ......

Page 78: ...Page 77 FIGURE 31...

Page 80: ...Page 79 FIGURE 32...

Page 82: ...Page 81 FIGURE 33...

Page 84: ...Page 83 FIGURE 34...

Page 86: ...Page 85 FIGURE 35...

Page 88: ...Page 87 FIGURE 36...

Page 90: ...Page 89 FIGURE 37...

Page 92: ...14 0 WIRING DIAGRAMS Page 91 045345 Scotchman Inds PART NO...

Page 93: ...3 5PB 1PL 045345 Scotchman Inds PART NO 1 3 Page 92 Ser s B1392HFANF0314 Up Part of Next Page...