Page 48

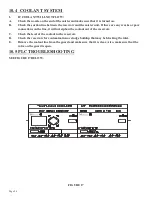

10.6 PNEUMATIC SYSTEM

REFER TO FIGURE 18 ON THE FOLLOWING PAGE.

THE MOST COMMON PNEUMATIC/HYDRAULIC PROBLEMS ARE:

A.

Low levels of fluid in the reservoirs: The fluid level in the power down feed reservoir should be

approximately 1-1/2 inches below the top of the reservoir with the head in the down position and

2-1/2 inches below the top of the reservoir when the head is in the up position. The fluid level in

the shuttle cylinder reservoir should be 1-1/2 inches below the top of the reservoir when the

cylinder is completely extended (all the way to the left, against the material vise).

CAUTION: THE AIR SUPPLY TO THE MACHINE MUST BE DISCONNECTED BEFORE

YOU REMOVE THE FILLER PLUG FROM THE RESERVOIRS. FAILURE TO

DISCONNECT THE AIR WILL CAUSE THE FLUID TO BE PURGED OUT THROUGH THE

OPENING UNDER PRESSURE!

B.

Worn seals in the vise or shuttle cylinders: For seal kit installation instructions, REFER TO

SECTIONS 8.6 & 8.7.

C.

Loose connections in the air lines: All of the air lines on this machine are the snap in connector

type. To remove the hose, push in on the slide connector while pulling out on the hose. To

reconnect the hose, simply push the hose into the connector as far as it will go. If there are any

questions about where the hoses connect, REFER TO FIGURE 18 ON THE FOLLOWING

PAGE.

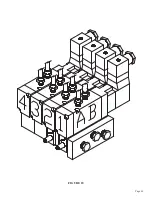

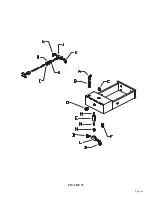

1A - 5/16" BLACK TO SAW VISE BACK

1B - 5/16" BLACK TO SAW VISE FRONT

2A - 1/4" RED TO TOP OF POWER DOWN HYD. TANK

2B - 1/4" GREEN TO BOTTOM OF POWER DOWN CYLINDER

3A - 1/4" BLUE TO RIGHT END OF SHUTTLE CYLINDER

3B - 5/16" BLACK TO TOP OF SHUTTLE HYD. TANK

4A - 1/4" BLACK TO BACK OF SHUTTLE VISE

4B - 1/4" YELLOW TO FRONT OF SHUTTLE VISE

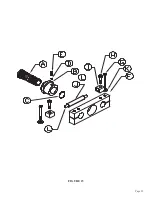

FLOW CONTOL VALVE - POWER DOWN - SAW VISE

RIGHT SIDE - 3/8" BLACK TO TEE UNDER POWER DOWN HYD. TANK

LEFT SIDE - 3/8" BLACK TO STRAIGHT FITTING UNDER POWER DOWN HYD. TANK

3/8" BLACK FROM TEE UNDER POWER DOWN HYD. TANK TO CYL. TOP

FLOW CONTROL VALVE - SHUTTLE

1/2" BLACK FROM VALVE TO LEFT END SHUTTLE CYLINDER

AS VIEWED FROM FRONT OF MACHINE

Summary of Contents for CPO-315-HFA-NF

Page 8: ...Page 7 FIGURE 1...

Page 10: ...Page 9 FIGURE 2...

Page 14: ...Page 13 FIGURE 3...

Page 18: ...Page 17 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 22: ...Page 21 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 23: ...Page 22 6 3 MATERIAL MAIN VISE SEE FIGURE 6 BELOW FIGURE 6...

Page 25: ...Page 24 FIGURE 7...

Page 27: ...Page 26 6 6 POWER DOWN FEED REFER TO FIGURE 8 BELOW FIGURE 8...

Page 30: ...Page 29 FIGURE 9...

Page 31: ...Page 30 6 9 COUNTER SET UP REFER TO FIGURE 10 BELOW FIGURE 10...

Page 33: ...Page 32 7 0 MACHINE AUTOMATIC OPERATION SET UP REFER TO FIGURE 11 BELOW FIGURE 11...

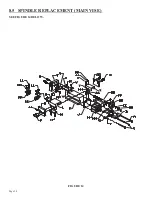

Page 37: ...Page 36 8 4 SPINDLE SHAFT REPLACEMENT REFER TO FIGURE 13 BELOW FIGURE 13...

Page 39: ...Page 38 8 5 SPINDLE REPLACEMENT MAIN VISE SEE FIGURE 14 BELOW FIGURE 14...

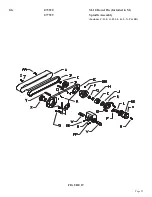

Page 41: ...Page 40 8 7 SHUTTLE VISE MAINTENANCE SEE FIGURE 15 BELOW FIGURE 15...

Page 44: ...Page 43 FIGURE 16...

Page 50: ...Page 49 FIGURE 18...

Page 56: ......

Page 60: ...Page 59 FIGURE 23...

Page 62: ...Page 61 FIGURE 24...

Page 64: ...Page 63 FIGURE 25...

Page 66: ...Page 65 FIGURE 26...

Page 68: ...Page 67 FIGURE 27...

Page 70: ...Page 69 FIGURE 28...

Page 72: ...Page 71 FIGURE 29...

Page 75: ......

Page 76: ......

Page 78: ...Page 77 FIGURE 31...

Page 80: ...Page 79 FIGURE 32...

Page 82: ...Page 81 FIGURE 33...

Page 84: ...Page 83 FIGURE 34...

Page 86: ...Page 85 FIGURE 35...

Page 88: ...Page 87 FIGURE 36...

Page 90: ...Page 89 FIGURE 37...

Page 92: ...14 0 WIRING DIAGRAMS Page 91 045345 Scotchman Inds PART NO...

Page 93: ...3 5PB 1PL 045345 Scotchman Inds PART NO 1 3 Page 92 Ser s B1392HFANF0314 Up Part of Next Page...