6.5 MITER LOCKING DEVICE

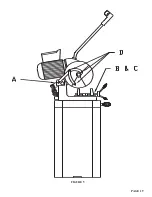

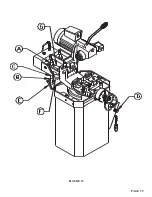

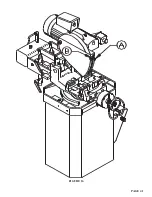

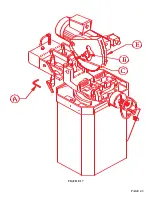

SEE FIGURE 10 ON THE FOLLOWING PAGE.

All models manufactured for domestic sales are equipped with a miter locking device which allows quick

set-up for mitering at 45 degrees, left and right, and 90 degrees for straight cutting. A miter locking

device is available as an option for models manufactured for international sales.

TO USE THE MITER LOCKING DEVICE:

1. Unlock the tension handle (A).

2. Push the miter lock release handle (B).

3. Turn the head in the direction that you want to miter.

4. Release the miter lock handle and continue turning the head until the pin snaps into the slot.

5. Then, re-lock the tension handle. When locking the tension handle, do not over-tighten.

6. The miter locking device can be fine adjusted if it does not stop at an exact 45. Loosen the mounting

bolts (F) and adjust the complete miter lock, left or right, to the desired position.

IF YOU WANT TO CUT MITERS OTHER THAN 45 DEGREES:

1. Unlock the tension handle (A).

2. Push the miter lock release handle (B) and turn the head to the desired angle by using the scale on the

saw.

NOTE: THE SCALE IS READ ON THE RIGHT SIDE OF THE VISE AT POINT (C), NOT IN THE

CENTER.

3. Re-lock the tension handle (A). After a period of time, the tension handle (A) may need to be adjusted

if the head will not remain in the position that it was previously set.

TO RE-SET THE TENSION HANDLE:

1. Remove the access panel on the back of the machine base.

2. Move the tension handle (A) to its unlocked position.

3. Loosen the jam nuts (D) on the adjustment bolts (E) and tighten the bolts finger tight, plus 1/4 of a

turn.

4. Work the tension handle several times and re-tighten the adjusting bolts, if necessary.

5. Re-tighten the jam nuts (D).

PAGE 28

Summary of Contents for CPO 350

Page 1: ...CPO 350 VARIABLE SPEED COLD SAW PRINTED SEPTEMBER 2014...

Page 7: ...PAGE 7 FIGURE 1...

Page 8: ...4 2 MACHINE MOVING PROCEDURES SEE FIGURE 2 BELOW PAGE 8 FIGURE 2...

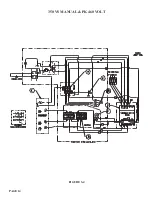

Page 11: ...PAGE 11 350 VS POWER DOWN 230 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 1...

Page 12: ...PAGE 12 350 VS MANUAL PK 230 VOLT FIGURE 3 2...

Page 13: ...PAGE 13 350 VS POWER DOWN 460 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 3...

Page 14: ...PAGE 14 350 VS MANUAL PK 460 VOLT FIGURE 3 4...

Page 17: ...PAGE 17 FIGURE 4...

Page 19: ...PAGE 19 FIGURE 5...

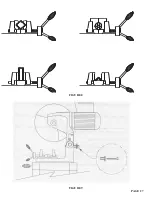

Page 27: ...PAGE 27 FIGURE 8 FIGURE 9...

Page 29: ...PAGE 29 FIGURE 10...

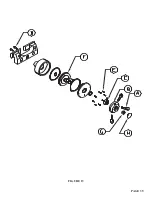

Page 33: ...PAGE 33 FIGURE 12...

Page 35: ...PAGE 35 FIGURE 13...

Page 37: ...PAGE 37 FIGURE 14...

Page 39: ...PAGE 39 FIGURE 15...

Page 41: ...PAGE 41 FIGURE 16...

Page 43: ...PAGE 43 FIGURE 17...

Page 45: ...7 2F POWER DOWN FEED WIRING DIAGRAM Ser s 6425 Up PAGE 45 FIGURE 19...

Page 46: ...7 2G PNEUMATIC SCHEMATIC POWER DOWN MACHINES PAGE 46 FIGURE 20...

Page 47: ...THIS PAGE LEFT BLANK INTENTIONALLY PAGE 47...

Page 49: ...PAGE 49 FIGURE 21...

Page 51: ...PAGE 51 FIGURE 22...

Page 55: ...PAGE 55 FIGURE 23...

Page 59: ...PAGE 59 FIGURE 25...

Page 61: ...PAGE 61 FIGURE 26...

Page 63: ...PAGE 63 FIGURE 27...

Page 65: ...PAGE 65 FIGURE 28...

Page 67: ...PAGE 67 FIGURE 29...

Page 69: ...PAGE 69 FIGURE 30...

Page 71: ...PAGE 71 FIGURE 31...

Page 73: ...PAGE 73 FIGURE 32...

Page 75: ...PAGE 75 FIGURE 33...

Page 77: ...PAGE 77 FIGURE 33...

Page 79: ...PAGE 79 FIGURE 34...

Page 81: ...PAGE 81 FIGURE 35...

Page 83: ...PAGE 83 FIGURE 36...

Page 85: ...PAGE 85 FIGURE 37...

Page 87: ...PAGE 87 FIGURE 38...

Page 89: ...PAGE 89 FIGURE 39...

Page 91: ...PAGE 91 FIGURE 40...

Page 93: ...PAGE 93 FIGURE 41...