7.2 POWER DOWN FEED

The power down feed option, used in conjunction with the power vise option, changes a manual saw into

a semi-automatic saw. These options will increase productivity and reduce operator fatigue. The power

down feed option cannot be retrofit to machines with serial number 11940491 and prior in the field. This

option can be used on machines with or without the power vise option.

7.2A POWER DOWN FEED SET-UP AND MAINTENANCE

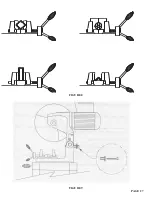

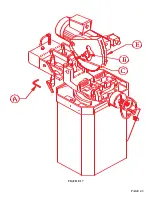

SEE FIGURE 14 ON THE FOLLOWING PAGE.

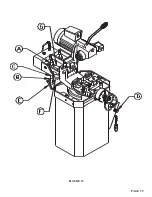

1. Before powering the saw, check the oil level in the reservoir (A). There is a sight glass in the

reservoir. The saw head must be in the UP position to check the level. The recommended oil is a 10

wt., non-foaming hydraulic oil.

Ö

CAUTION: ALWAYS DISCONNECT THE AIR SUPPLY BEFORE REMOVING THE FILLER

PLUG FROM THE RESERVOIR. IF THE FILLER PLUG IS REMOVED WHILE THE

MACHINE IS CONNECTED TO THE AIR PRESSURE, THE FLUID IN THE TANK WILL BE

PURGED THROUGH THE OPENING UNDER PRESSURE.

2. Slide the shuttle valve (D) to its CLOSED position and connect the air supply.

3. Slide the shuttle valve to its OPEN position and adjust the air pressure regulator.

90 PSI (6.2 BAR) is the minimum operating pressure. 105 PSI (7.2 BAR) is the maximum.

4. Without powering the saw, manually cycle the head up and down several times, to purge the air out of

the lines. The head may cycle irregularly the first few cycles.

5. After cycling the head, shut the flow control valve (B) off. Then, open it one turn.

6. There is a down feed pressure regulator mounted on the down feed cylinder. The regulator maintains

a constant down feed pressure when cutting profiles with varying wall thicknesses.

PAGE 36

Summary of Contents for CPO 350

Page 1: ...CPO 350 VARIABLE SPEED COLD SAW PRINTED SEPTEMBER 2014...

Page 7: ...PAGE 7 FIGURE 1...

Page 8: ...4 2 MACHINE MOVING PROCEDURES SEE FIGURE 2 BELOW PAGE 8 FIGURE 2...

Page 11: ...PAGE 11 350 VS POWER DOWN 230 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 1...

Page 12: ...PAGE 12 350 VS MANUAL PK 230 VOLT FIGURE 3 2...

Page 13: ...PAGE 13 350 VS POWER DOWN 460 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 3...

Page 14: ...PAGE 14 350 VS MANUAL PK 460 VOLT FIGURE 3 4...

Page 17: ...PAGE 17 FIGURE 4...

Page 19: ...PAGE 19 FIGURE 5...

Page 27: ...PAGE 27 FIGURE 8 FIGURE 9...

Page 29: ...PAGE 29 FIGURE 10...

Page 33: ...PAGE 33 FIGURE 12...

Page 35: ...PAGE 35 FIGURE 13...

Page 37: ...PAGE 37 FIGURE 14...

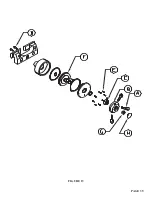

Page 39: ...PAGE 39 FIGURE 15...

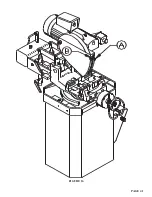

Page 41: ...PAGE 41 FIGURE 16...

Page 43: ...PAGE 43 FIGURE 17...

Page 45: ...7 2F POWER DOWN FEED WIRING DIAGRAM Ser s 6425 Up PAGE 45 FIGURE 19...

Page 46: ...7 2G PNEUMATIC SCHEMATIC POWER DOWN MACHINES PAGE 46 FIGURE 20...

Page 47: ...THIS PAGE LEFT BLANK INTENTIONALLY PAGE 47...

Page 49: ...PAGE 49 FIGURE 21...

Page 51: ...PAGE 51 FIGURE 22...

Page 55: ...PAGE 55 FIGURE 23...

Page 59: ...PAGE 59 FIGURE 25...

Page 61: ...PAGE 61 FIGURE 26...

Page 63: ...PAGE 63 FIGURE 27...

Page 65: ...PAGE 65 FIGURE 28...

Page 67: ...PAGE 67 FIGURE 29...

Page 69: ...PAGE 69 FIGURE 30...

Page 71: ...PAGE 71 FIGURE 31...

Page 73: ...PAGE 73 FIGURE 32...

Page 75: ...PAGE 75 FIGURE 33...

Page 77: ...PAGE 77 FIGURE 33...

Page 79: ...PAGE 79 FIGURE 34...

Page 81: ...PAGE 81 FIGURE 35...

Page 83: ...PAGE 83 FIGURE 36...

Page 85: ...PAGE 85 FIGURE 37...

Page 87: ...PAGE 87 FIGURE 38...

Page 89: ...PAGE 89 FIGURE 39...

Page 91: ...PAGE 91 FIGURE 40...

Page 93: ...PAGE 93 FIGURE 41...