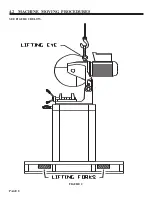

This machine is shipped on a pallet and can be moved to the installation location by means of a forklift.

Ö

CAUTION: THIS MACHINE IS TOP HEAVY AND MUST BE MOVED WITH CARE, ON HARD

FLAT SURFACES ONLY.

All saws, except models equipped with the power down feed option, are shipped with the head locked in

the DOWN position. Before lifting the machine, release the head by opening the material vise and

allowing it to move to the UP position. Lift the machine, using the lifting eyelet provided. SEE FIGURE

2 ON THE PRECEDING PAGE. Remove the pallet and place the machine in its final location. This

machine is top heavy and must be anchored to the floor.

4.3 PHYSICAL INSPECTION

Once the machine is located, check it for any possible damage incurred in shipment. Remove the lifting

eyelet and install the draw handle.

Ö

CAUTION: DO NOT USE THE LIFTING EYELET FOR ANY MACHINES OTHER THAN THIS

SAW. MAKE SURE THAT THE DRAW HANDLE HAS A JAM NUT ON THE THREADS

BEFORE INSTALLING IT ON THE SAW. IF THE HANDLE IS INSTALLED WITHOUT THE

JAM NUT, IT MAY CONTACT THE GEARS INSIDE THE HEAD.

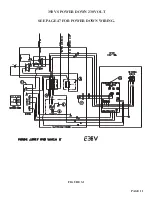

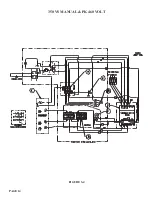

After the draw handle has been installed on manual and power vise machines, remove the cover from the

electrical control box and connect the trigger switch wires. REFER TO FIGURE 3-1.

Remove any other packing material and draw the saw head to its DOWN position to make sure that the

guard opens properly. The guard should close completely when the head is up and open freely as the

head travels down.

If the guard is not functioning properly, REFER TO SECTION 4.6 FOR THE MANUAL MACHINES

OR SECTION 7.2C FOR MACHINES EQUIPPED WITH THE POWER DOWN FEED OPTION.

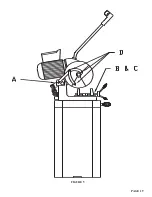

With the head in the UP position, check the oil level in the gear box through the sight glass in the

casting just below the draw handle.

If your saw is equipped with either the power vise or the power down feed option, REFER TO

SECTIONS 7.1 THRU 7.2, for additional information.

PAGE 9

Summary of Contents for CPO 350

Page 1: ...CPO 350 VARIABLE SPEED COLD SAW PRINTED SEPTEMBER 2014...

Page 7: ...PAGE 7 FIGURE 1...

Page 8: ...4 2 MACHINE MOVING PROCEDURES SEE FIGURE 2 BELOW PAGE 8 FIGURE 2...

Page 11: ...PAGE 11 350 VS POWER DOWN 230 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 1...

Page 12: ...PAGE 12 350 VS MANUAL PK 230 VOLT FIGURE 3 2...

Page 13: ...PAGE 13 350 VS POWER DOWN 460 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 3...

Page 14: ...PAGE 14 350 VS MANUAL PK 460 VOLT FIGURE 3 4...

Page 17: ...PAGE 17 FIGURE 4...

Page 19: ...PAGE 19 FIGURE 5...

Page 27: ...PAGE 27 FIGURE 8 FIGURE 9...

Page 29: ...PAGE 29 FIGURE 10...

Page 33: ...PAGE 33 FIGURE 12...

Page 35: ...PAGE 35 FIGURE 13...

Page 37: ...PAGE 37 FIGURE 14...

Page 39: ...PAGE 39 FIGURE 15...

Page 41: ...PAGE 41 FIGURE 16...

Page 43: ...PAGE 43 FIGURE 17...

Page 45: ...7 2F POWER DOWN FEED WIRING DIAGRAM Ser s 6425 Up PAGE 45 FIGURE 19...

Page 46: ...7 2G PNEUMATIC SCHEMATIC POWER DOWN MACHINES PAGE 46 FIGURE 20...

Page 47: ...THIS PAGE LEFT BLANK INTENTIONALLY PAGE 47...

Page 49: ...PAGE 49 FIGURE 21...

Page 51: ...PAGE 51 FIGURE 22...

Page 55: ...PAGE 55 FIGURE 23...

Page 59: ...PAGE 59 FIGURE 25...

Page 61: ...PAGE 61 FIGURE 26...

Page 63: ...PAGE 63 FIGURE 27...

Page 65: ...PAGE 65 FIGURE 28...

Page 67: ...PAGE 67 FIGURE 29...

Page 69: ...PAGE 69 FIGURE 30...

Page 71: ...PAGE 71 FIGURE 31...

Page 73: ...PAGE 73 FIGURE 32...

Page 75: ...PAGE 75 FIGURE 33...

Page 77: ...PAGE 77 FIGURE 33...

Page 79: ...PAGE 79 FIGURE 34...

Page 81: ...PAGE 81 FIGURE 35...

Page 83: ...PAGE 83 FIGURE 36...

Page 85: ...PAGE 85 FIGURE 37...

Page 87: ...PAGE 87 FIGURE 38...

Page 89: ...PAGE 89 FIGURE 39...

Page 91: ...PAGE 91 FIGURE 40...

Page 93: ...PAGE 93 FIGURE 41...