THERE ARE FOUR STYLES OF BLADES AVAILABLE:

STYLE 2: Has a round back tooth with a square face and top. This style is designed for thin wall,

nonferrous tubes, plastics and synthetics.

STYLE 2A: Is an alternate top bevel grind. This grind is used on blades that have 240 teeth or more.

Applications for this style are thin wall tubes, profiles with thin cross sections and nonferrous

applications that require 240 teeth or more.

STYLE 3: Is a triple chip grind with a high/low tooth form. This grind is used on blades that have

220 teeth or less. This style is used for a wide range of materials from solid sections of nonferrous

materials to heavy wall tubes and solid sections of steel and alloys.

POWER 2000: Is a notch grind blade designed for use on fully and semi-automatic machines with the

variable speed control, only. This style is designed for .100 wall or thinner tube with a minimum blade

speed of 170 RPM.

The stock blades listed above are oxide coated high speed steel. Ten inch (250mm) blades can be

provided with any number of teeth, from 50 to 280.

SERIAL #’S B8001 & UP

PAGE 95

No high, No low, Power 2000 Blade

Alternate Grind

Triple Chip Grind

No bevel

with Notch Grind

Plastic at

Low RPM

.100 wall or thinner

with 170 RPM

Thin wall tube

Low RPM

Solid material &

thick wall pipe

Low RPM

Summary of Contents for CPO 350

Page 1: ...CPO 350 VARIABLE SPEED COLD SAW PRINTED SEPTEMBER 2014...

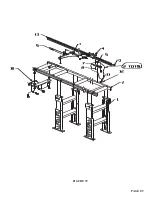

Page 7: ...PAGE 7 FIGURE 1...

Page 8: ...4 2 MACHINE MOVING PROCEDURES SEE FIGURE 2 BELOW PAGE 8 FIGURE 2...

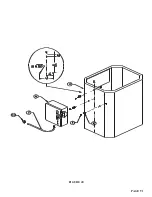

Page 11: ...PAGE 11 350 VS POWER DOWN 230 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 1...

Page 12: ...PAGE 12 350 VS MANUAL PK 230 VOLT FIGURE 3 2...

Page 13: ...PAGE 13 350 VS POWER DOWN 460 VOLT SEE PAGE 47 FOR POWER DOWN WIRING FIGURE 3 3...

Page 14: ...PAGE 14 350 VS MANUAL PK 460 VOLT FIGURE 3 4...

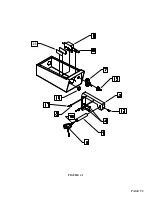

Page 17: ...PAGE 17 FIGURE 4...

Page 19: ...PAGE 19 FIGURE 5...

Page 27: ...PAGE 27 FIGURE 8 FIGURE 9...

Page 29: ...PAGE 29 FIGURE 10...

Page 33: ...PAGE 33 FIGURE 12...

Page 35: ...PAGE 35 FIGURE 13...

Page 37: ...PAGE 37 FIGURE 14...

Page 39: ...PAGE 39 FIGURE 15...

Page 41: ...PAGE 41 FIGURE 16...

Page 43: ...PAGE 43 FIGURE 17...

Page 45: ...7 2F POWER DOWN FEED WIRING DIAGRAM Ser s 6425 Up PAGE 45 FIGURE 19...

Page 46: ...7 2G PNEUMATIC SCHEMATIC POWER DOWN MACHINES PAGE 46 FIGURE 20...

Page 47: ...THIS PAGE LEFT BLANK INTENTIONALLY PAGE 47...

Page 49: ...PAGE 49 FIGURE 21...

Page 51: ...PAGE 51 FIGURE 22...

Page 55: ...PAGE 55 FIGURE 23...

Page 59: ...PAGE 59 FIGURE 25...

Page 61: ...PAGE 61 FIGURE 26...

Page 63: ...PAGE 63 FIGURE 27...

Page 65: ...PAGE 65 FIGURE 28...

Page 67: ...PAGE 67 FIGURE 29...

Page 69: ...PAGE 69 FIGURE 30...

Page 71: ...PAGE 71 FIGURE 31...

Page 73: ...PAGE 73 FIGURE 32...

Page 75: ...PAGE 75 FIGURE 33...

Page 77: ...PAGE 77 FIGURE 33...

Page 79: ...PAGE 79 FIGURE 34...

Page 81: ...PAGE 81 FIGURE 35...

Page 83: ...PAGE 83 FIGURE 36...

Page 85: ...PAGE 85 FIGURE 37...

Page 87: ...PAGE 87 FIGURE 38...

Page 89: ...PAGE 89 FIGURE 39...

Page 91: ...PAGE 91 FIGURE 40...

Page 93: ...PAGE 93 FIGURE 41...