PAGE 26

5.0 MAINTENANCE

The Scotchman Ironworker is an exceptionally rugged machine, designed for long life with a minimum

amount of maintenance. A regular program of servicing will extend the life of the machine and prevent

costly down time.

5.1 LUBRICATION

IMPORTANT: Before operating this machine, apply oil to the notcher, rod shear, angle shear,

bar shear blades and the punch and die.

Re-oil punches and dies every 5 to 10 holes and blades every 10 to 15 cuts. The oil will allow the machine

to shear, punch and strip easier and increase tool life considerably. We recommend cutting oil or motor

oil swabbed on with a brush or applied with a squirt can or a spray applicator.

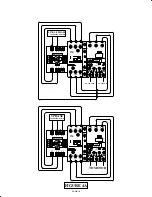

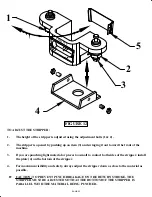

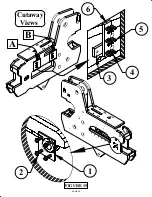

Grease the punch ram bushing (1) and the main pins (2, 3, & 4) daily. Grease all other fittings twice per

week. To gain access to the two punch pins, rotate the cover (5) up out of the way by loosening the two

bolts. The bottom hole in the cover is slotted. SEE FIGURE 9 ON THE FOLLOWING PAGE.

All grease locations are indicated with decals shown below.

Mobil Grease XHP 222 Special is recommended.

Once a month, check the oil level in the reservoir. It should be approximately 2 inches (50mm) below the

top of the reservoir.

The recommended hydraulic oil is a lightweight, non-foaming, hydraulic oil such as Mobil DTE 25 or

equivalent, with a minimum ISO cleanliness code of 20/18/15. The reservoir capacity is 14 U.S. gallons

(53 liters).

GREASE POINT

GREASE POINT