PAGE 38

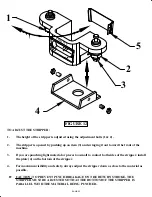

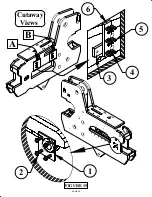

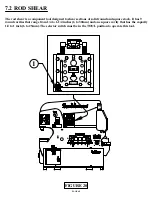

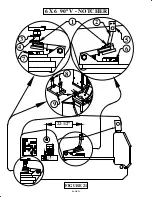

Adjustment on the shear arm is maintained on the front (operator’s) side by the pressure plate (1) and

on the rear by rub blocks (3 & 6) in two locations: A & B.

USE THE FOLLOWING STEPS TO ADJUST THE SHEAR ARM.

SEE FIGURE 15 ON THE FOLLOWING PAGE.

1.

Before making these adjustments, loosen the lower blade and back it away from the upper blade.

After making these adjustments, reset the blades following the instructions in SECTION 6.2B.

2.

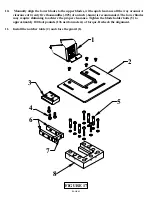

In locations A & B, loosen the six adjusting set screws (5) for each frame rub block (6) and remove

the rub blocks by taking out the three mounting bolts (4) that are between the set screws.

Look at the fiber rub blocks (3) that are bolted to the shear beam. If excessive concave wear is

noted with these rub blocks, they can be turned and the back surface used.

Set the pressure plate adjustment before resetting these rub blocks!!

3.

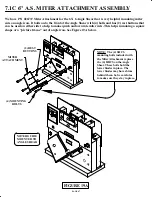

For the pressure plate adjustment, loosen the lock nuts (2) on the four adjusting screws that

engage the pressure plate (1).

4.

Tighten all four adjusting screws on the pressure plate so that they are "snug" and will force the

shear arm solidly against the rear frame. (Excessive tightening of these screws only increases

wear.)

5.

Starting with location A, replace the rub block (3). With the shear arm in the down position,

tighten the bottom two adjusting set screws (5) until the rub block comes in contact with the

shear arm rub block (6). Raise the arm about halfway and adjust the middle two adjusting

set screws (5) until the rub block makes contact. Then, raise the arm completely and adjust

the top set screws. (Once again, excessive tightening will cause unnecessary wear.) Check to

be sure that the rub block (3) is in contact with the shear arm rub block (6) throughout the

full stroke.

6.

Go to location B and repeat the above. When finished with location B - Make sure that the

rub block (3) is in contact with the shear arm rub block (6) throughout the full stroke in

both locations A & B.

7.

Make sure all the bolts (4) and set screws (5) are sufficiently tight and will stay.

8.

Tighten the lock nuts (2) on the pressure plate adjusting screws.

9.

SHEAR BLADE WILL NEED TO BE ADJUSTED - SEE SECTION 6.2B .

6.2A SHEAR ARM ADJUSTMENT