PAGE 40

6.2B SHEAR BLADE ADJUSTMENT PROCEDURE

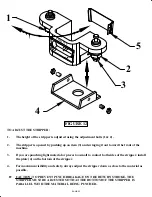

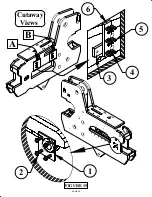

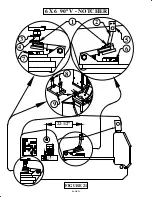

SEE FIGURE 16 ON THE FOLLOWING PAGE.

1.

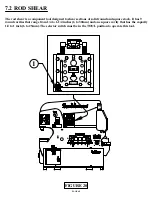

Place the selector switch in the SHEAR position and allow the arms to raise completely.

2.

Crank the hold-down devise all the way up and remove the shear table.

3.

To remove the shear table, loosen the jam nuts (6) on the bolts (3) and remove the bolt. Remove

the lower blade bolts (2) and back the adjustment screws (1) out.

4.

Remove the lower blade.

5.

Power the machine and place the selector switch in the PUNCH position. Allow the arm to travel

to its full down position. Turn the power off.

6.

Rotate "end-for-end" or replace the upper shear blade. (See "CAUTION" above)

7.

Rotate or replace the lower blade and start the socket head retaining bolts (2).

8.

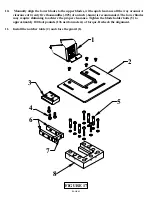

Place a shim with the desired clearance between the upper and lower blades.

9.

Adjust the lower blade to the top blade, with the upper adjusting screws (1), about 1/8 of a turn

past resistance.

10.

Tighten the bolts (2) to 1/4 a turn past resistance.

11.

Adjust the lower adjusting screws (1) up to the blade and then, tighten all of the bolts, starting

with the blade bolts (2) and then, the adjusting screws (1).

12.

CAUTION: THE BLADES MUST BE ADJUSTED PARALLEL TO EACH OTHER, vertically or

with the cutting edge of the lower blade at a slight cant towards the upper blade.

13.

Power the machine and place the selector switch in the SHEAR position. With the foot pedal, cycle

the shear down slowly, watching the blade engagement. Make sure that the blades do not contact

each other.

14.

Replace the shear table (4). If needed, the shear table can be adjusted to match the lower blade.

15.

The table is adjusted with the four screws (5).

►

If the machine is being used to shear maximum capacities, we recommend increasing the

clearance. A clearance of five to seven percent of the material thickness is recommended.

CAUTION: Cutting Edge Is Curved On Upper Blade!! It has just TWO cutting edges.

IT CAN ONLY BE ROTATED END-FOR-END!!