PAGE 44

►

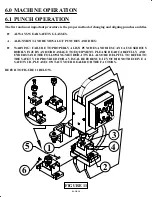

CAUTION: MOVE ALL TOOLS OUT FROM UNDER THE

UPPER ARM WHEN THEY ARE NOT IN USE.

When using the tool station, remove the punch and die.

As with all functions on this machine, SAFETY GLASSES ARE REQUIRED when using optional tools

of any type.

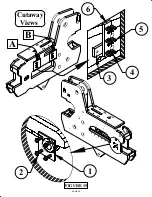

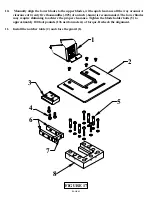

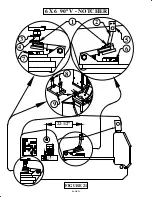

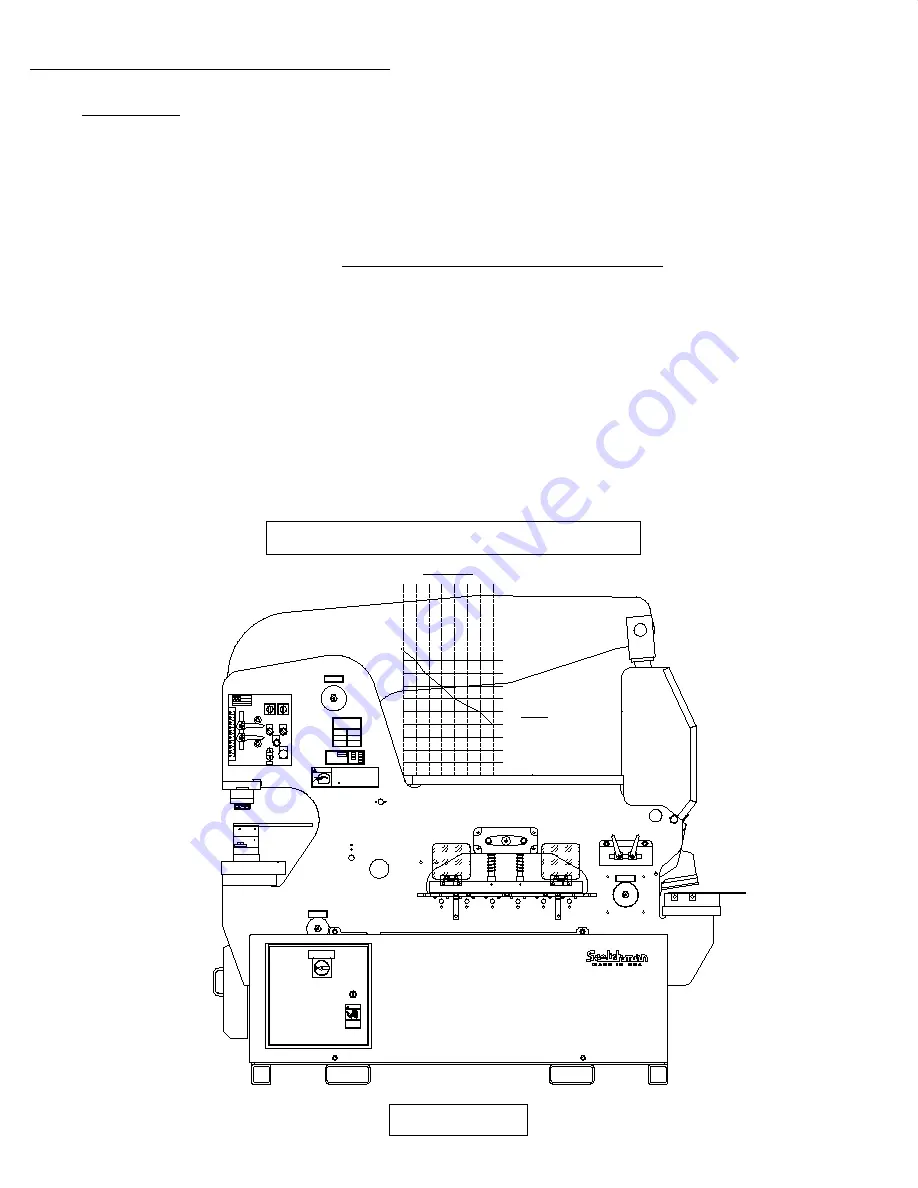

Each self contained tool has its own stroke and tonnage requirements. This section will over the

operation and location of each tool. On the following page, there is a graphical illustration of the

available tonnage at locations along the upper arm.

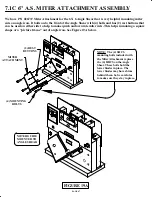

SEE FIGURE 18 BELOW.

This graph will be helpful in setting up various Scotchman or custom tooling.

7.0 OPTIONAL TOOLS

TOOL TABLE - AVAILABLE TONNAGE

FIGURE 18

33131 Assy

4185

013180

13179

201110

M6x12

201110

M6x12

201110

M6x12

201110

M6x12

013180

13179

201110

M6x12

201110

M6x12

201110

M6x12

201110

M6x12

17341

080435 Assy.

080430

230210

230210

13220 - 3ph 13225 - 1ph

230 Volts

19121

OFF

EATON

11856

ELECTRICAL HAZARD

Turn off power

and lock out

before servicing.

DANGER

3122

1213

25525 Raw

224205

224205

33176

80155

080174

243101

Assy.

13190

080061

080061

WARNING

SAFETY GLASSES REQUIRED WHEN

OPERATING OR OBSERVING THIS MACHINE

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

TO PREVENT SERIOUS BODILY INJURY

Operate, install tooling, service or adjust machine without

operator's manual and safety film.

Service machine with electrical power connected.

Operate any station without the respective strippers or

Operate machine with protective guards removed.

Place any part of your body under blade, punch or moving

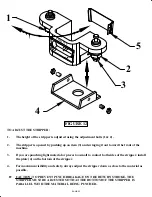

Operate punch station without checking the punch to die

alignment and tightness.

Punch half holes, punch or shear unknown materials, side load

DO NOT REMOVE THIS SIGN FROM THIS MACHINE

REV. 0310

FOR MORE INFORMATION CONTACT SCOTCHMAN INDUSTRIES INC.

1-800-843-8844

003100

proper instructions and without reading and understanding the

hold-downs in place.

members.

(Check alignment and tightness daily.)

press brakes.

AT

SERIAL

SCOTCHMAN INDUSTRIES, INC.

PHILIP, SOUTH DAKOTA, U.S.A.

MADE IN U.S.A.

MODEL

FLA

HZ

PH

H.P.

VOLT

BLADE LENGTH

PH. 605-859-2542

PSI

PUNCH

120 TONS

Ø38 THRU 25MM

Ø1-1/2 THRU 1.0"

FLAT SHEAR

1 X 12" - 1/2 X 24"

BLADE LENGTH 24" - 600MM

25X300 - 12X600MM

THROAT DEPTH

12" - 305MM

RECT. NOTCHER

76X127X12MM

3"X5"X1/2"

PUNCH STROKE

2.25" - 57MM

ANGLE SHEAR

150X150X12MM

6"X6"X1/2"

DUAL OPERATOR

1xx/2xx - 24M

MACHINE CAPACITIES

SPEC. BASED ON MILD STEEL-65,000 PSI TENSILE

#033184

5,03

33149

33156

80191

80211

80197

33018

80424 F

224205

224205

224205

224205

33157

13268

080174

243101

Assy.

080174

243101

Assy.

80156 Sales

033047

LUBRICATE

BEFORE

OPERATING

19103

0481

LUBRICATE

BEFORE

OPERATING

19103

0481

LUBRICATE

BEFORE

OPERATING

19103

0481

JOG

3200

STOP

START

START

RUN JOG

PUNCH

TOOL

RUN PROBE

SHEAR

NOTCH

START

MM.

IN.

MM.

IN.

90

80

70

60

50

40

30

20

10

10

90

80

70

60

50

40

30

20

3

2

1

3

2

1

0

004085

213012

213012

201240

201240

033707

080061

080061

15440

26710

6013

201640

113017

113017

20

30

40

50

60

70

80

90

100

0

TONS

DISTANCE

2 4 6 8 10 12 14