PAGE 49

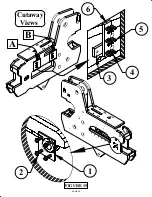

7.2A ROD SHEAR INSTALLATION

SEE FIGURE 20 ON THE PRECEDING PAGE.

The rod shear mounts in the tool station under the upper arm and is held in place with the finger clamps

(1) provided.

Since the rod shear requires a short stroke, (approximately 1/2 inch (12mm) and has no slug, it can be

operated at any practical location under the upper arm. Care must be taken to align the pressure block

of the tool squarely under the upper arm.

►

CAUTION: TO PREVENT DAMAGE TO THE TOOL, THE STROKE OF THE MACHINE

MUST BE SET WHEN USING THE ROD SHEAR.

Set the upstroke of the machine so that the workpiece easily slides through the tool. Set the down stroke

so that the cut can be made with a minimum amount of stroke.

Failure to set the stroke of the machine will damage the tool.

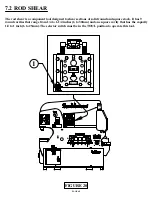

7.2B ROD SHEAR OPERATION

Oil the blades before starting and every 10 to 15 cuts, thereafter. Grease the slider block between the tool

and the arm every two hours of operation. On all round sizes, select the proper cavity for the size being

sheared. In the square cavity, there is a kick-up bolt adjustment. Adjust this bolt so that the workpiece

will just feed under the bolt and remains horizontal to the shear.

►

CAUTION: WHEN SHEARING SHORT PIECES OR NIPPING THE ENDS OF THE ROD,

CARE SHOULD BE TAKEN SO THAT THE SLUGS DO NOT BUILD UP IN THE DROP-OFF

SIDE. IF THIS HAPPENS, THERE IS A POSSIBILITY OF INJURY TO OTHER PERSONNEL

AND DAMAGE TO THE TOOL. ALWAYS REMOVE THE ROD SHEAR WHEN IT IS NOT

IN USE.

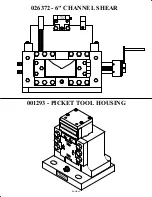

026278

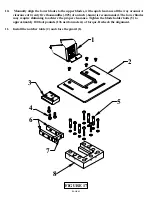

026775

026776

026283

026283

201110

M6x12

201235

M10x80

026779

201415

M12x40

026746

026746

221210

M10 x 25

221210

M10 x 25

204225

M10 x 60

204225

M10 x 60

026744 Rod Shear

Complete Tool

220016

201215

M10x40

201215

M10x40

201215

M10x40

201215

M10x40

203235

M10x90

203235

M10x90

203235

M10x90

203235

M10x90

203235

M10x90

203235

M10x90