PAGE 50

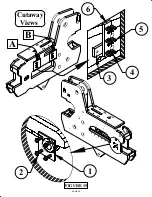

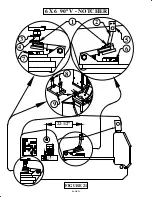

7.3 6 X 6 90° V - NOTCHER

The 6 x 6 ninety degree notcher is a component tool designed to cut 90 degree vee notches in angle and

flat stock. It has a maximum capacity of 5/16 of an inch (8mm) thickness mild steel.

7.3A 6 X 6 90° V - NOTCHER INSTALLATION

7.3B 6 X 6 90° V - NOTCHER OPERATION

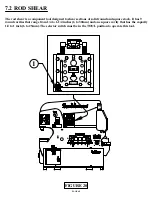

Lubricate the blades before starting and every 10 to 15 cuts, thereafter. Do not attempt to shear material

thicker than 5/16 OF AN INCH (8mm) and never side-load the notcher. The slug must be removed with

a magnetic probe or tongs after every cut.

►

DO NOT REMOVE THE SLUGS BY HAND.

►

ALWAYS REMOVE THE NOTCHER WHEN IT IS NOT IN USE.

SEE FIGURE 21 ON THE FOLLOWING PAGE

The 6 x 6 ninety degree notcher can be mounted either under the upper arm on the tool table or in the

punch station.

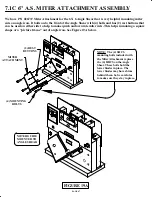

When mounted on the tool table, the selector switch for the PUNCH/TOOL station must be in the TOOL

position.

When the notcher is mounted in the punch station, the selector switch for the PUNCH/TOOL station must

be in the PUNCH position.

►

CAUTION: IN EITHER STATION, CARE MUST BE TAKEN TO SET THE UPPER AND

LOWER STROKE CONTROLS ON THE MACHINE. FAILURE TO SET THE STROKE

CONTROLS WILL RESULT IN DAMAGE TO THE TOOL AND POSSIBLE INJURY TO THE

OPERATOR.

The pusher is attached to notcher by the notcher clip (1) and the pusher assembly should be under spring

tension of the tool. The lower stroke must be set so that the upper blade just passes the lower blades at the

point of the vee by no more than 1/16 of an inch (1.5mm).

To install the notcher under the upper arm, the tool should be mounted as close to the frame as possible

and anchored with the bolts (6) provided. The pusher (2) and beam block (5) should be installed as shown

in FIGURE 21. NOTE: A distance of 22-1/2" between the main pin and block (5) is ideal.

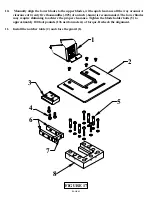

To mount the notcher in the punch station, first remove the punch, die, die holder and stripper. Then

install the riser (9) on top of the punch bolster with the four 16mm SHCS (8) provided. Mount the short

punch pusher (3) with the jam nut. Mount the notcher to the punch table with the front of the notcher

extending past the front of the punch table about a 5/16 inch. SEE FIGURE 21. Secure the notcher to the

punch table with the heavy washer and bolt (7) provided. Punch pusher (3) and notcher pusher (4) should

align as shown with the punch pusher toward the front of the notcher pusher.

After the notcher is mounted, install the neoprene slug pad.