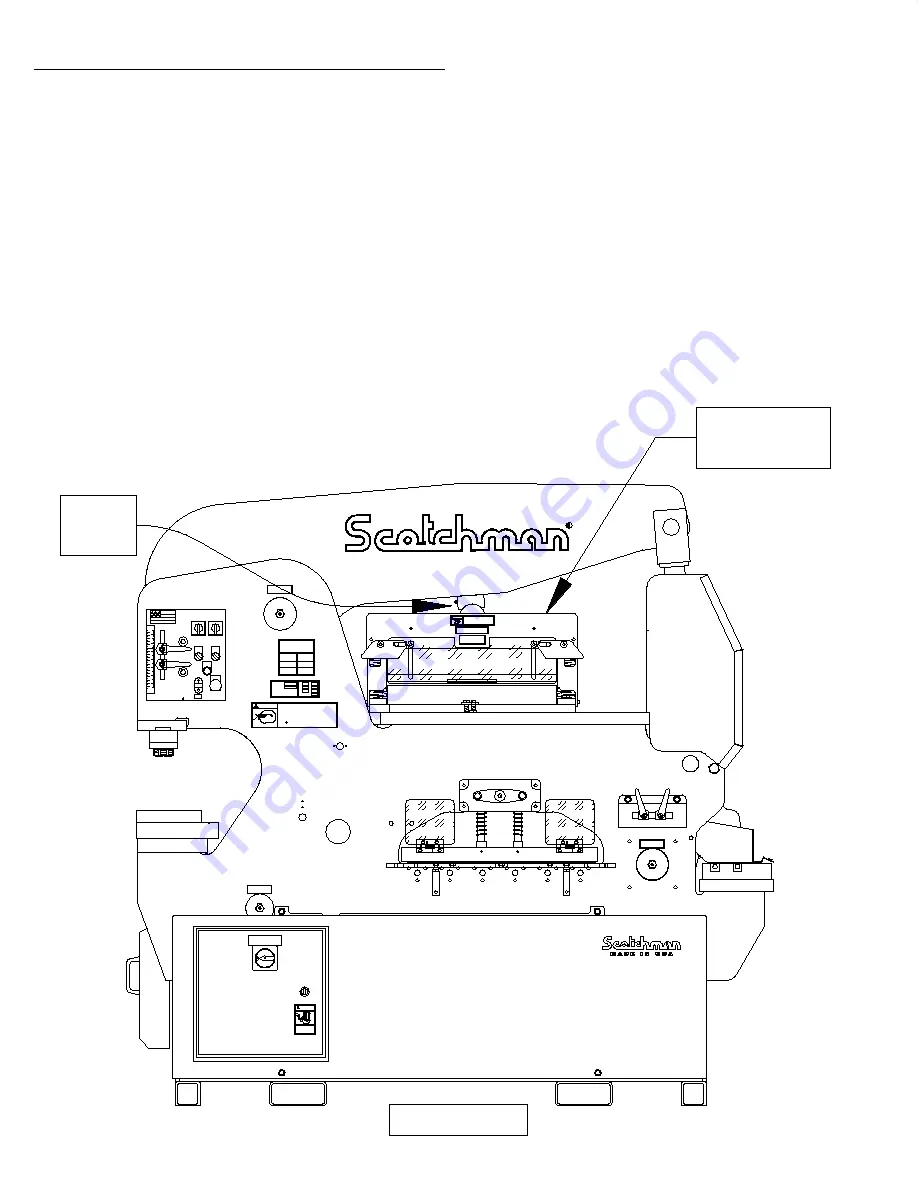

FIGURE 22

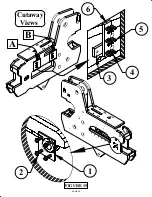

7.4B BRAKE OPERATION

NEVER PUT YOUR HANDS INTO OR AROUND A BRAKE WHILE IT IS IN OPERATION.

Hold short pieces with tongs or a similar device. When using the brake, it is necessary to load the brake

centrally. (Visual centering is sufficient.) If work is performed off-center, the guide pins could be

damaged. The brake lift is provided by springs. If sticking occurs at the bottom of the stroke and the

upper die does not return, a slight tap on the upper die is usually sufficient to free the guides.

DO NOT ATTEMPT TO FREE THE BRAKE BY HAND.

Sticking can be caused by lack of lubrication, complexity of the part being bent or bent guide pins.

Keep the guides well lubricated and replace them, if damaged. It is common practice to have the

bottom die opening 8 times the thickness of the material being bent. If the parts require a bend of

less than 90 degrees, adjust the down stroke of the machine until the desired bend is obtained. A

great variety of standard brake dies can be used with this unit. These are available from Scotchman

Industries or brake die suppliers.

ALWAYS REMOVE THE TOOL WHEN IT IS NOT IN USE.

Slider

Block

24" Brake

Shown

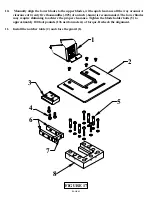

037003 Assy

4185

013180

13179

201110

M6x12

201110

M6x12

201110

M6x12

201110

M6x12

013180

13179

201110

M6x12

201110

M6x12

201110

M6x12

201110

M6x12

17341

080435 Assy.

080430

230210

230210

13220 - 3ph 13225 - 1ph

230 Volts

19121

OFF

EATON

11856

ELECTRICAL HAZARD

Turn off power

and lock out

before servicing.

DANGER

3122

1213

25525 Raw

224205

224205

33176

80155

080174

243101

Assy.

13190

080061

080061

WARNING

SAFETY GLASSES REQUIRED WHEN

OPERATING OR OBSERVING THIS MACHINE

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

TO PREVENT SERIOUS BODILY INJURY

Operate, install tooling, service or adjust machine without

operator's manual and safety film.

Service machine with electrical power connected.

Operate any station without the respective strippers or

Operate machine with protective guards removed.

Place any part of your body under blade, punch or moving

Operate punch station without checking the punch to die

alignment and tightness.

Punch half holes, punch or shear unknown materials, side load

DO NOT REMOVE THIS SIGN FROM THIS MACHINE

REV. 0310

FOR MORE INFORMATION CONTACT SCOTCHMAN INDUSTRIES INC.

1-800-843-8844

003100

proper instructions and without reading and understanding the

hold-downs in place.

members.

(Check alignment and tightness daily.)

press brakes.

AT

SERIAL

SCOTCHMAN INDUSTRIES, INC.

PHILIP, SOUTH DAKOTA, U.S.A.

MADE IN U.S.A.

MODEL

FLA

HZ

PH

H.P.

VOLT

BLADE LENGTH

PH. 605-859-2542

PSI

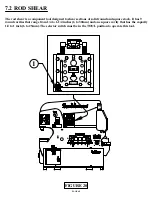

33149

010117

80191

80211

80197

33018

80424 F

33157

13268

224205

224205

224205

224205

080174

243101

Assy.

080174

243101

Assy.

80156 Sales

LUBRICATE

BEFORE

OPERATING

19103

0481

LUBRICATE

BEFORE

OPERATING

19103

0481

LUBRICATE

BEFORE

OPERATING

19103

0481

JOG

3200

STOP

START

START

RUN JOG

PUNCH

TOOL

RUN PROBE

SHEAR

NOTCH

START

MM.

IN.

MM.

IN.

90

80

70

60

50

40

30

20

10

10

90

80

70

60

50

40

30

20

3

2

1

3

2

1

0

004085

213012

213012

201240

201240

033707

080061

080061

80860

16362

16346

26303 - Brake

LUBRICATE

BEFORE

OPERATING

19103

0481

REMOVE TOOL WHEN NOT IN USE

AND/OR DAMAGE TO MACHINE

TO PREVENT SERIOUS BODILY INJURY

003145

WARNING

TO PREVENT SERIOUS BODILY INJURY

AND/OR DAMAGE TO MACHINE

DO NOT BRAKE ROUNDS

LOAD MATERIAL CENTRALLY

0398

003150

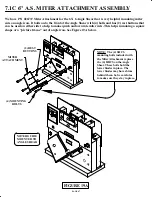

#037009

11,04

DUAL OPERATOR

150/240 - 24M

MACHINE CAPACITIES

SPEC. BASED ON MILD STEEL-65,000 PSI TENSILE

PUNCH

150 TONS

Ø47 THRU 25MM

Ø1-7/8 THRU 1.0"

FLAT SHEAR

1 X 14" - 3/4 X 24"

BLADE LENGTH 24" - 600MM

25X300 - 12X600MM

THROAT DEPTH

12" - 305MM

RECT. NOTCHER

76X127X12MM

3"X5"X1/2"

PUNCH STROKE

2.25" - 57MM

ANGLE SHEAR

150X150X12MM

6"X6"X1/2"

PAGE 53