PAGE 58

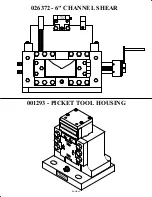

7.6 CHANNEL SHEAR

The Channel Shear is a component tool designed to shear 2 to 6 inch (51 to 152mm) standard channel on

this model. The PUNCH/TOOL selector switch must be in the TOOL position to operate this tool.

7.6A CHANNEL SHEAR INSTALLATION

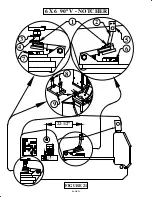

SEE FIGURE 25 ON THE NEXT PAGE.

The channel shear installs under the upper arm in the tool station. The PUNCH/TOOL selector switch

must be in the TOOL position to operate this tool. Before installing the tool, remove the upper blade.

Install the spring guide pins with the head down in the side plate of the shear. PLEASE SEE "UPPER

BLADE ASSY" in FIGURE 25. Slide the return springs over the guide pins, the short one first, followed

by the long one. Replace the top blade. Mount the shear as close to the frame as possible, with the hand

crank to the cylinder end of ironworker. Make sure that the slug slot in the tool aligns with the slug slot

in the tool table. Care must be taken to squarely align the tool under the upper arm. Anchor the tool

with the finger clamps provided.

7.6B CHANNEL SHEAR OPERATION

The channel shear will shear from 2 to 6 inch (51 to 152mm) standard channel with minimum distortion.

Lubricate the blades before the first cut and every 10 to 15 cuts, thereafter. Grease the slider block

between the tool and the arm every two hours of operation

The following are BASIC STEPS IN SHEARING WITH THE CHANNEL SHEAR.

A.

ADJUST BOTH THE MOVING AND STATIONARY SIDE BLADES TO THE SIZE OF

CHANNEL BEING SHEARED.

Improper adjustment of the vertical blades will result in damage to the channel shear. To keep the

channel centered in the unit, it is necessary to reset the stationary side blades for each size of channel.

ONE METHOD OF ACCOMPLISHING THIS ADJUSTMENT IS AS FOLLOWS:

Place a piece of channel, the size to be sheared, in the tool. Remove the lifting springs and lower the

upper blade by hand, until it contacts the channel iron. Locate the channel so that the upper blade

contacts both legs, which will center it in the shear. Adjust the vertical side blades with the hand crank

up to the flange of the channel. Loosen the (4) fixed vertical blade clamps (two in front & two in back with

three bolts each) and slide the fixed blades up to the channel flange. Tighten the blade clamps and adjust

the back-up socket set-screws up against the fixed vertical blades. Now, check to see that the blades have

good alignment, front and back, and have maintained their perpendicular position to the lower blades.

B.

POSITION THE ADJUSTING HANDLE.

The adjusting handle can be relocated to permit easy opening and closing of the movable vertical

blades. (Approximately 1/2 turn will lock and unlock the work piece.)