219045

M10x20

026435

026435

201250

M10x130

201250

M10x130

201250

M10x130

201250

M10x130

016184

016185

016184

016185

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

203225

M10x65

203212

M10x30

203225

M10x65

203225

M10x65

224005

M6x12

026191

026197

026746

026746

201110

M6x12

026438

026438

026209

204225

M10 x 60

204225

M10 x 60

PAGE 60

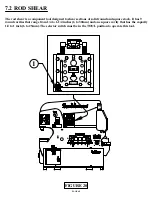

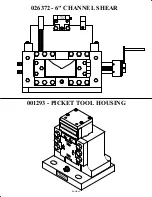

C. SET THE BOTTOM OF THE STROKE AS LOW AS POSSIBLE.

The bottom of the stroke should be set as low as possible, without bottoming any part of the upper blade,

blade holder or pressure The upper stroke should be set to allow the workpiece to feed freely through the

shear.

D. PROCEDURE FOR SHEARING.

Lubricate the blades before making the first cut and every 10 to 15 cuts, thereafter. This lubrication is

critical on the channel shear. Position the workpiece. Snug the movable blades up to the channel’s

flange. Depress the foot switch and shear the workpiece. Before releasing the foot switch, back the

movable blades off by 1/2 turn of the locking handle. Make sure that the slug drops from the chute after

each stroke. All of the bottom and vertical blades are symmetrical and can be turned to present four (4)

cutting edges. Clearance between the upper and lower blades is changed by the addition or removal of

shims. A clearance of twenty thousandths of an inch (.5mm) is recommended. For efficient shearing,

blades must be kept sharp.

►

A FEW SPECIAL PRECAUTIONS ◄

1.

The stationary blade adjustment on the tool must be made so that the point of the upper blade

makes contact with the channel directly in the center of the web.

2.

The crank adjustment must be used to clamp up the material prior to the cut and loosened after

the cut.

3.

Any systems used to feed the material must hold the material at a true horizontal plane.

4.

Do not place any part of your body in or near the blade and return spring area.

5.

Lubricate the blades every 10 to 15 cuts for maximum blade life.

►

CAUTION: TO PREVENT POSSIBLE INJURY TO PERSONNEL AND DAMAGE TO THE

TOOL, THIS TOOL MUST BE REMOVED WHEN IT IS NOT IN USE.

219045

M10x20

026435

026435

201250

M10x130

201250

M10x130

201250

M10x130

201250

M10x130

016184

016185

016184

016185

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

201420

M12x50

203225

M10x65

203212

M10x30

203225

M10x65

203225

M10x65

224005

M6x12

026191

026197

026746

026746

201110

M6x12

026438

026438

026209

204225

M10 x 60

204225

M10 x 60