PAGE 62

7.7 PIPE NOTCHER

The pipe notcher is a component tool designed to saddle cut pipe or tubing for applications such as

railings. There are dies available to notch angles in pipe and tubing, also. For prices and availability,

Contact your local dealer or the factory.

7.7A PIPE NOTCHER INSTALLATION

7.7B PIPE NOTCHER OPERATION

PLEASE READ CAREFULLY BEFORE USING.

To achieve the best results from your unit, please observe these simple rules:

A.

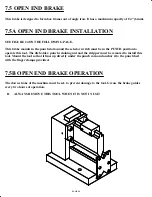

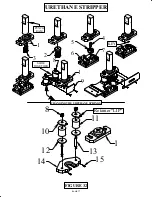

Keep the unit clean. Whenever dirt or metal chips accumulate, remove the 8mm limit screw

located in the center at the rear of the upper die. Lift out the upper die assembly and the two

springs (1/2 x 3"). Clean the unit with solvent.

B.

After cleaning the unit, always check the alignment of the upper and lower dies. To check the

alignment, insert the upper die and holder, without the springs, into the housing and check for

equal gap. SEE ►►►

The upper die should have a 3\16" pin that aligns with a groove in the lower die to insure alignment.

Tighten the two M-10 socket head screws holding the die section in place. Apply some high pressure

lube all around the inside of the housing, then re-assemble the unit, reversing the above procedures.

►

CAUTION: WHEN USING THIS TOOL, ALWAYS WEAR SAFETY GLASSES.

Before operation, lubricate the sides and back of the upper die with way oil. Repeat this

lubrication once daily. Cutting blades should be lubricated with a cutting oil or motor oil, before

making the first cut and after every 10 to 15 cuts.

SEE FIGURE 26 ON THE NEXT PAGE.

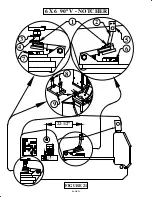

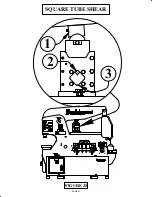

The pipe notcher can be installed in either the punch station or under the upper arm. When installed on

the tool table, the PUNCH/TOOL selector switch must be in the TOOL position. When installed in the

punch station, the PUNCH/TOOL selector switch must be in the PUNCH position. When installing the

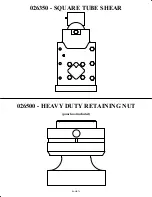

notcher in the punch station, remove the die holder and the stripper. Install the pusher (2) on the punch

ram using the #45 punch retaining nut (1). Attach the riser (3) to the tool. Set the notcher on the bolster

and align the slug hole in the notcher with the hole in the bolster. Anchor the tool with the finger clamps

(4) that are provided.

To mount the notcher on the tool table, attach the riser (3) and the pusher (5) to

the tool and align the slug hole in the tool with the slug hole in the tool table. Anchor the tool to the tool

table with a bolt and washer (7) that are provided.

►

CAUTION: WITH THE TOOL MOUNTED IN EITHER STATION, IT IS NECESSARY TO

SET THE DOWNSTROKE OF THE MACHINE TO PREVENT DAMAGE TO THE TOOL.

THE UPPER DIE SHOULD NOT PASS THE LOWER DIE BY MORE THAN 1/32 OF AN

INCH (.7MM).