PAGE 68

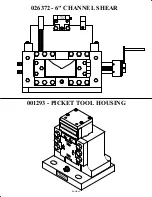

7.10A OFFSET DIE HOLDER FOR FLANGE PUNCHING

The offset die holder is used for punching holes in the flange of structural shapes such as channel, I-beam

and H-beam. The offset die holder is installed in place of the standard die holder.

Use the same method of installing and aligning punches and dies as outlined in SECTION 6.1, with the

following exceptions:

The punch retaining nut, punch and die must be inserted in the die holder before the machine is powered

and placed in the PUNCH position.

The down stroke of the machine must be set to prevent damage to the tool and possible injury to the

operator.

Because of its design, the maximum punching capacity of the offset die holder is forty (40) tons.

SEE FIGURE 29

►

CAUTION: THE OFFSET DIE HOLDER MUST BE REMOVED WHEN IT IS NOT IN USE.

►

FOR SIZES AND APPLICATION, SEE THE TOOLING PARTS MANUAL.

Always follow the preferred method of aligning punches and dies. SEE SECTION 6.1.

The 2-1/2 and 3 inch (63 and 76mm) die holders are used in place of the standard die holder. These die

holders are for oversized punching. SEE FIGURE 29

►

FOR SIZES AND APPLICATIONS, SEE THE #40 TOOLING PARTS MANUAL.

7.10B 2-1/2 AND 3 INCH (63 AND 76 MM) DIE HOLDERS

Always follow the preferred method of aligning punches and dies. SEE SECTION 6.1.

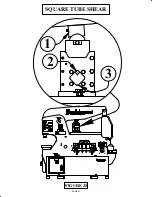

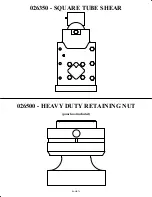

The 6 x 6 die holder is used in place of the standard die holder. This 6 x 6 die holder is provided with a

riser plate that must be used with this model and mounted with the bolts provided.

Capacities for oversize punching with this tool go up to 4 inches (102mm). SEE FIGURE 29

►

FOR SIZES AND APPLICATION, SEE THE #40 TOOLING PARTS MANUAL.

7.10C 6 X 6 DIE HOLDER

7.10 OPTIONAL DIE HOLDERS &

PUNCH RETAINING NUTS