25310

25312 Assy.

25315

29220

29220

29220

25311

25314

25317 Assy.

25320

25361

25361

253324

219047M10x12

221420

M16x50

221420

M16x50

221420

M16x50

221420

M16x50

PAGE 72

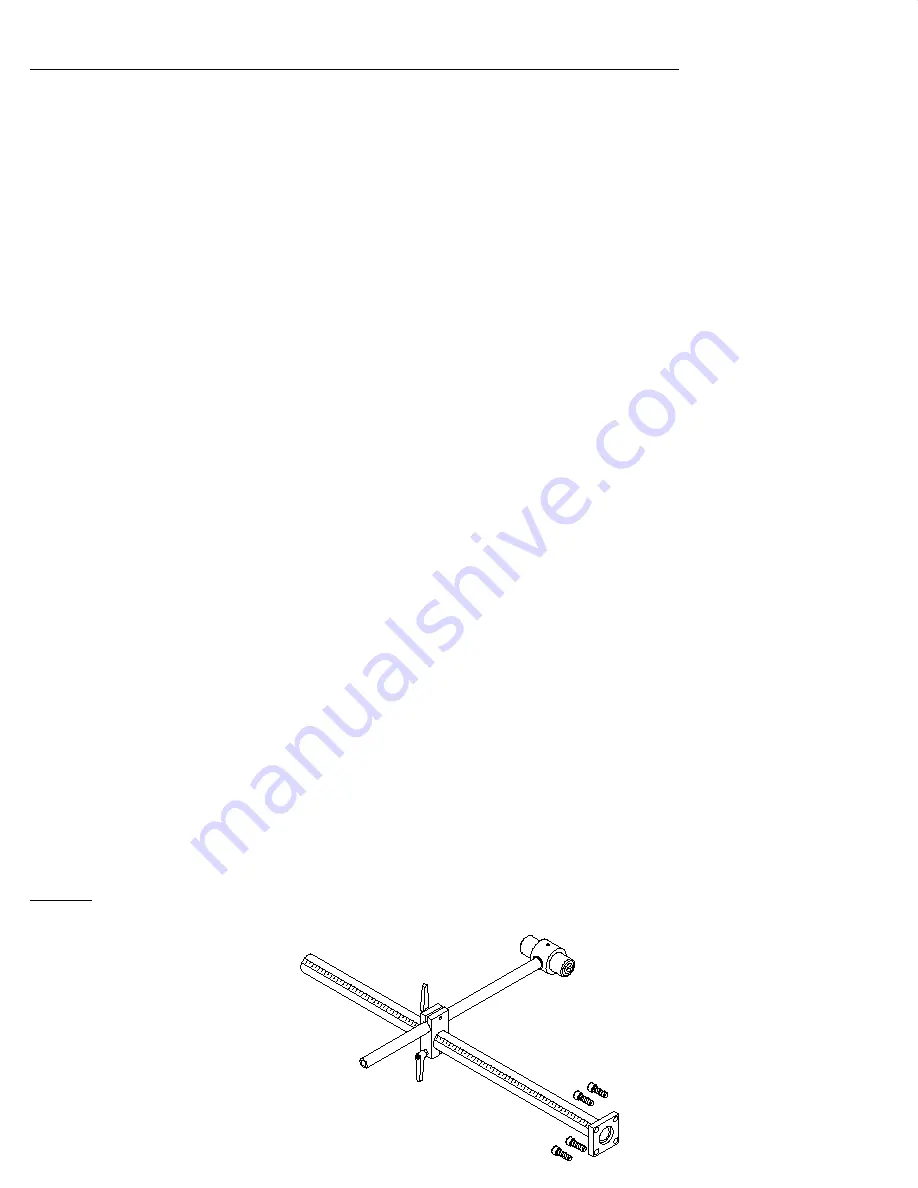

7.11 FORTY-EIGHT INCH BACK GAUGE

This back gauge (P/N 025603) is designed to fit a wide range of models. The mounting location is on the

back, or drop off side, of the machine. Please see the attached drawing. A few models have two mounting

locations, depending upon how far apart the work stations are. Because this is a universal tool, there are a

few things you need to do to complete the set-up for your particular model.

1.

First, mount the main tube, Item (7), to the machine, using the bolts provided.

2.

Assemble the balance of the back gauge per the attached drawing.

3.

Slide the balance of the assembly on the main tube (7) so that the slide block (6) is as close to the

machine's frame as possible and lined up with the plate shear on your model. Lock the slide in

place.

►

PLEASE NOTE that the locking handles are a ratchet type handle. If they contact the frame of

the machine when tightening them, pull the handle out and ratchet it back to continue tightening.

4.

Once the slide block (6) is tightened to the main tube, loosen the set screw (4) and slide the probe

in as close the bottom shear blade as possible.

5.

On some models, the probe will reach the lower shear blade. On these models, lock the set screw

(4) with the probe against the shear blade and install the scale (8) on the main tube with 0 inches

aligned with the slide block (6).

6.

On models where the probe does not reach the lower shear blade, set the probe at a set distance

away from the lower blade such as 1 or 2 inches. If the probe is 1 inch from the lower blade install

the scale with the 1 inch mark aligned with the slide block (6).

7.

When you move the probe to another station, you will have to re-calibrate the stop by moving the

slide block (6) in to the preset point on your scale and loosening the set screw (4) and adjusting the

probe accordingly.

8.

The other important thing is to set the probe where it contacts the material you are going to cut.

FIGURE 31 on the next page shows the recommended placement of the probe in relation to the

material being cut. . If the probe is not properly set, the material can move the probe and cause

changes in the length of your parts.

NOTE: There is also an Electric Back Gauge (P/N 026610) available for this machine. Contact your

dealer, or call the factory at 1-605-859-2542 for more information.

SCOTCHMAN INDS. - 180 E US HWY 14 - PO BOX 850 - PHILIP, SD 57567 Call: 1-605-859-2542