PAGE 74

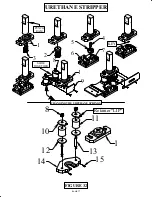

7.12 URETHANE STRIPPER

Scotchman does not recommend this unit for all general punching applications. However, using this

specially designed "Non Deform" stripper unit does offer a significant advantage over a standard

stripper arrangement in reducing distortion when punching a confined pattern or series of holes in flat

bar or plate.

NOTE: THIS STRIPPER ONLY WORKS WITH #40 TOOLING. THE MAXIMUM HOLE

SIZES THAT CAN BE PUNCHED ARE 1-1/4 (31mm) ROUND AND OVAL AND 3/4 (19mm)

SQUARE.

The action of this unit will minimize distortion in the work piece and in many cases eliminate costly

correction and straightening processes. Of course, there is a limit how much material can be removed in

a confined area without causing some deformation. Contact your dealer or Scotchman for advice.

Combining this unit with a linear feed repetitive stop system for punching a series of holes in flat bar will

significantly increase productivity. Because of the action of this type of unit, particular attention must be

paid when setting the stroke length. The stripper unit moves in conjunction with the punch and extra

care must be taken by the operator. (Refer to the setting and operating instructions in this section.)

The maximum thickness which can be punched using this unit is 1" (25mm) in steel with a rated tensile

strength of 65,000 lbs. psi.

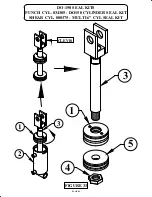

STRIPPER, PUNCH & DIE

7.12A INSTALLING THE URETHANE

REFER TO FIGURE 32

1.

Raise the top limit switch to its highest position. Power the machine and let the punch ram retract to

its full UP position.

2.

Open the standard stripper and remove it from the machine by removing the left hand mounting

bolt.

3.

If there is a punch and die installed in the machine, remove them.

4.

Loosen the two bolts (6) holding the die holder (7).

5.

Remove the punch holder (2) from the end of the ram.

6.

Disassemble the urethane stripper by removing the two retaining nuts (8).

7.

Install the stripper mounting plate (1) and the punch holder (2) to the ram, with the bolts provided.

8.

Select the proper punch and die. Make sure that there is proper clearance between the punch and

die. For recommended clearances:

GO TO SECT. 6.1 "PUNCH OPERATION" - LETTER "I"