PAGE 76

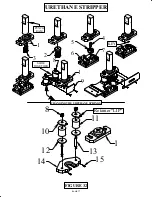

7.12B CHANGING THE URETHANE SPRINGS

25451

25453

25453

25443

25443

25455

25455

25456

25456

25454

25454

25447

25450

73691

M6x12

73691

M6x12

006202

204220

M10x30

219060

218056

218056

26038

220014

220014

26082

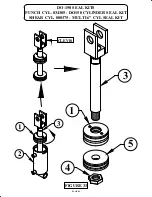

WARNING

1/16" MIN. CLEARANCE

BETWEEN PUNCH & DIE

0209

003130

MFG. BY THE DORKY FUCKING GLASSES CO. LTD.

SAFTEY GLASSES REQUIRED

WHEN OPERATION OR

OBSERVING THIS MACHINE

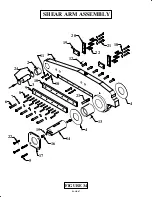

SEE FIGURE 32

If the unit is constantly over stroked or over a period of time, it may be necessary to renew the urethane

springs. REFER TO FIGURE 32. The springs should be checked periodically. (A sure sign of over

stroking is cracking or splitting of the springs.)

1.

Secure the unit in a vise by clamping the bottom plate (14). Loosen and remove both nyloc

nuts (8) & retainers (10). If one or both tie rods (13) become loose when loosening the nyloc nuts,

remove the loose tie rod from the base plate and remove the nuts (8) from the tie rod. Re-tighten

the tie rod into the base plate and lock in place, using a thread locking solution on the set-screws

(15) such as Blue Loctite. ®

2.

Remove items (10) and (8), top plate (1).

3.

Remove both of the urethane springs (11) and spring spacers (12).

4.

Reassemble the unit with new urethane springs

6. Tighten both retaining nuts (8) to achieve the correct setting distance.