PAGE 83

If the machine stops instead of returning when the foot switch is released, the problem is in the limit

switch.

Check the limit switch plunger to make sure that it is operating freely. The limit switch can be tested

with an Ohm meter. The limit switch wires must be disconnected from the terminal block to test it. The

switch should have continuity with the plunger out and open with the plunger depressed. Call the factory

for help if needed.

8.2 CONTROL VALVE INSPECTION

THE MACHINE WILL ONLY TRAVEL IN ONE DIRECTION.

This could be caused by:

1.

CONTAMINATION IN THE HYDRAULIC OIL WHICH

CAUSES THE SPOOL TO STICK IN ONE POSITION:

With the machine’s power off, the spool of the valve can be manually shifted. To shift the spool manually,

on each end of the control valve, there is a pin in the center of the knurled nut that holds the

coil on. Using a small punch or similar device, push these pins in by hand, first one and then, the other.

After manually shifting the spool, turn the machine on and try it again. If the machine now operates, the

hydraulic oil and the filter should be changed.

2.

A DEFECTIVE COIL ON THE CONTROL VALVE:

The coils can be checked using an Ohm meter. The wires to the coils must be disconnected. If the ohm

reading shows open, the coil is defective and must be replaced.

8.3 HYDRAULICS

THE MOST COMMON HYDRAULIC PROBLEMS ARE:

1.

Low level of hydraulic oil in the reservoir: The reservoir holds 14 U.S. gallons (53 liters). The level

should be approximately 2 inches (50mm) below the top of the reservoir.

2.

Contamination in the hydraulic oil: The oil and the filter should be changed at least once a year

and any time there is a possibility that contamination has gained access into the system.

FOR THE RECOMMENDED HYDRAULIC OIL, SEE SECTION 5.2.

3.

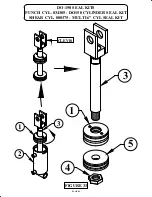

Low pressure caused by worn or damaged parts in the cylinders or pumps: There is a pressure

port for a pressure gauge provided on all machines. The port will be on the valve manifold. A

gauge with a minimum capacity of 4,000 PSI (276 BAR) is required. With the machine’s power

off, install the pressure gauge.