Page 11

3.

To execute the program:

A - To select line of beginning.

B - To continue the program in the last line in execution.

C - To execute the program from the first line.

When the machine is prepared for the execution of the program, follow the steps below:

1.

Adjust the desired height of the cut, using the travel end stop at the right of the machine.

2.

Position the machine hold-down clamps and the feeder gripper close enough to the material so that

they do not travel more than 5 millimeters (2/10 of an inch).

It is important that the horizontal hold-down clamp of the feeder gripper is a maximum of 5mm

from the material. If not, it will not allow the machine to be turned.

3.

Position the bar over the feeder so that it passes by about 10mm (4/10 of an inch) from the saw blade

groove.

4.

Fasten the material by operating the hold-down clamps of the feeder gripper.

5.

Start the working cycle by pressing the START button.

The machine will stop automatically when the material is finished, the stop button is pressed, the

alarm is produced or when the program is finished. During the work of the machine, we can see

the measures of the part in execution.

Summary of Contents for GAA-500-90 CNC DT20

Page 1: ...PRINTED OCTOBER 2020 MODEL GAA 500 90 CNC DT20 AUTO UPCUT COLD SAW WWW SCOTCHMAN COM...

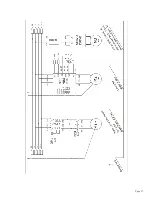

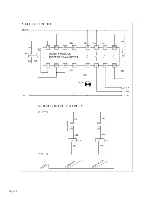

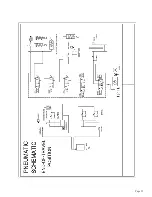

Page 16: ...Page 16 7 0 DRAWINGS AND SCHEMATICS...

Page 17: ...Page 17...

Page 18: ...Page 18...

Page 19: ...Page 19...

Page 20: ...Page 20...

Page 21: ...Page 21...

Page 23: ...29 LEFT SIDE CLAMP RIGHT SIDE CLAMP 17 Page 23...