8.0 MAIN FRAME ASSEMBLY

ITEM PART # DESCRIPTION

1 2059000064 Working plate

2 2050000322 Roker support

3 2050000322 Roker

4 2040000072 Rocker rotation shaft

5 TD12500012 M-12 washer

6 TD91212025 DIN 912 M-12 x 25 PIN

7 2059007522 7.5 HP III phase motor

8 2169000142 Motor pulley J16

9 TD93110050 DIN 931 M-10 x 50 PIN

10 2050000092 Rectified Ø100 shaft

11 2040000172 4206 bearing

12 Separators

13 2169000132 Rocker pulley J16

14 205DW35032 Ø500 blade

15 2050000032 Blade washer

16 2040000232 Blade nut

17 1283 Poly Belt For GAA-500 7.5hp Ref# 1283

17A C2050000012 J12 Poly V-Belt - Older 5.5hp saws use this belt

18 2059000024 Turret

19 Left turret plate

20 Right turret plate

21 TD69120616 DIN 6912 M-6 x 16 PIN

22 2040000062 Ø45 Aluminum rod

23 B000001070 M-10 x 70 Pull

24 1677 Ø45 Pneumatic hold-down clamp

25 2350000131 Nylon cleat

26 2090000191 Ø36 Horizontal rod

27 B000006x40 M-10 x 40 Pull

28 C2070000295 Ø36 x 225 Pneumatic clamp

29 2050000172 GAA Clamp Block

30 Blade groove GAA-500

31 DIN 7991 M-6 PIN

Page 22

5167

Summary of Contents for GAA-500-90 CNC DT20

Page 1: ...PRINTED OCTOBER 2020 MODEL GAA 500 90 CNC DT20 AUTO UPCUT COLD SAW WWW SCOTCHMAN COM...

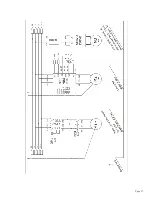

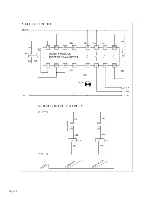

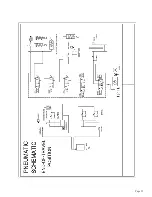

Page 16: ...Page 16 7 0 DRAWINGS AND SCHEMATICS...

Page 17: ...Page 17...

Page 18: ...Page 18...

Page 19: ...Page 19...

Page 20: ...Page 20...

Page 21: ...Page 21...

Page 23: ...29 LEFT SIDE CLAMP RIGHT SIDE CLAMP 17 Page 23...