Page 18

5.5 GENERAL RULES & SAFETY CHECKS

Before using the machine, check the efficiency and perfect operation of all safety devices and check

that the moving parts of the machine are not blocked, that there are no damaged parts and that all

machine components are positioned and work correctly.

All safety devices must be kept in working order.

DO NOT operate this machine without the protective shield in position.

ALWAYS wear gloves and protective eyewear.

ALWAYS wear regulation work clothes that are not loose fitting and are fastened.

Before starting work, the operator must ensure that all tools and wrenches used for maintenance or

adjustment have been removed.

In the event of a fire, use powder extinguishers and disconnect the machine from the electric system.

6.0 RECOMMENDATIONS AND MAINTENANCE

6.1 TYPE & FREQUENCY OF INSPECTIONS

The operator’s knowledge of the machine is one of the best ways of daily control of any possible problem.

If any failure is detected, work must be stopped and qualified personnel must be informed immediately.

NOTE: Always clean the machine and the work area at the end of the workday.

MAINTENANCE TABLE

AREA TO INSPECT

FREQUENCY

INSPECTION PROCEDURE

Level of cutting coolant

DAILY

Feeder guides

WEEKLY

Clean & lubricate w/SAE 30

Blade raise guides

WEEKLY

Clean & lubricate w/SAE 30

Saw motor exhaust

WEEKLY

Clean off cuttings while the

machine is disconnected

End stops

WEEKLY

Clean off cuttings & check condition

Motor belt

MONTHLY

Clean off cuttings & check condition

Summary of Contents for GAA-500-90 NF

Page 1: ...PRINTED OCTOBER 2020 Page 1 MODEL GAA 500 90 NF AUTO UPCUT COLD SAW WWW SCOTCHMAN COM...

Page 9: ...Page 9...

Page 11: ...Page 11 FIGURE 1...

Page 13: ...Page 13 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 15: ...Page 15 FIGURE 2 FIGURE 3...

Page 16: ...Page 16 FIGURE 5...

Page 17: ...Page 17 FIGURE 6...

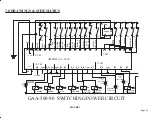

Page 22: ...Page 22 POWER CIRCUIT FIGURE 8...

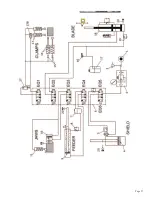

Page 23: ...Page 23 FIGURE 9...

Page 27: ...Page 27...

Page 29: ...Page 29 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 31: ......

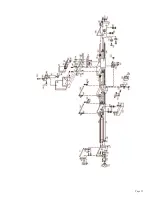

Page 32: ...Page 32 12 0 SHUTTLE FEED SYSTEM...

Page 33: ...Page 33...