Page 19

6.2 QUALIFIED PERSONNEL FOR MAINTENANCE

All repairs shall be made exclusively by qualified personnel, thereby always using original

replacement parts. If not, the machine may be damaged or the user may be injured.

The maintenance and cleaning of the machine must not be neglected. The life of the machine and its

optimal operation depend on it considerably.

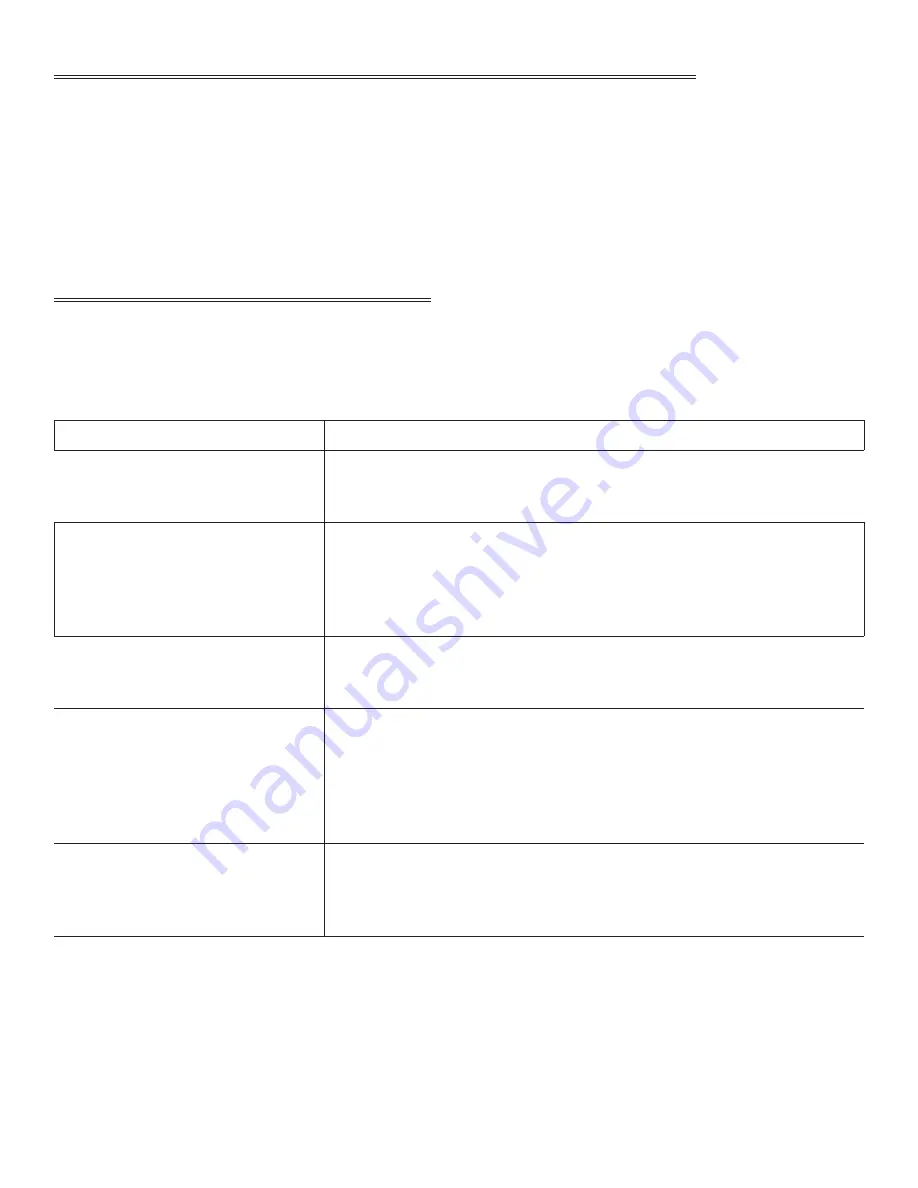

6.3 POSSIBLE BREAKDOWNS

BREAKDOWN

CHECK

None of the machine components

work.

Check that there is voltage at the input and output of the main switch.

Check the control circuit fuse.

Check the condition of the transformer and the contactor.

The feeder does not work correctly.

Check the status of all end-of-travel stops and the positioning of the

same. Check the condition of all electrovalbves.Check the condition of

the automata (feeder box) and the voltage on the line itself. (110 VAC)

Check the pressure at the regulator (6 atm) and the condition of the air

tubes.

The shield-raised indicator does not

turn off.

Ensure that the automata is not receiving a signal at input ch103. If it is,

check the detector

located on the shield cylinder.

The blade does not raise correctly.

Check the level of the hydraulic oil in the converter located inside the

feeder, through the rear

access sheet metal panel.

Check the pressure at the filter - regulator.

Check that the advance may be too high.

Check the “raise blade” pushbuttons.

The feeder does not move correctly.

Check the level of the hydraulic oil.

Check the filter - regulator pressure.

Check that the advance may be too high.

Check the “raise blade” pushbuttons.

Summary of Contents for GAA-500-90 NF

Page 1: ...PRINTED OCTOBER 2020 Page 1 MODEL GAA 500 90 NF AUTO UPCUT COLD SAW WWW SCOTCHMAN COM...

Page 9: ...Page 9...

Page 11: ...Page 11 FIGURE 1...

Page 13: ...Page 13 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 15: ...Page 15 FIGURE 2 FIGURE 3...

Page 16: ...Page 16 FIGURE 5...

Page 17: ...Page 17 FIGURE 6...

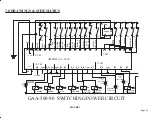

Page 22: ...Page 22 POWER CIRCUIT FIGURE 8...

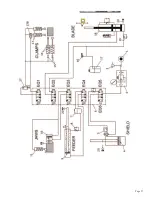

Page 23: ...Page 23 FIGURE 9...

Page 27: ...Page 27...

Page 29: ...Page 29 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 31: ......

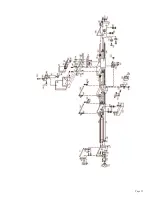

Page 32: ...Page 32 12 0 SHUTTLE FEED SYSTEM...

Page 33: ...Page 33...