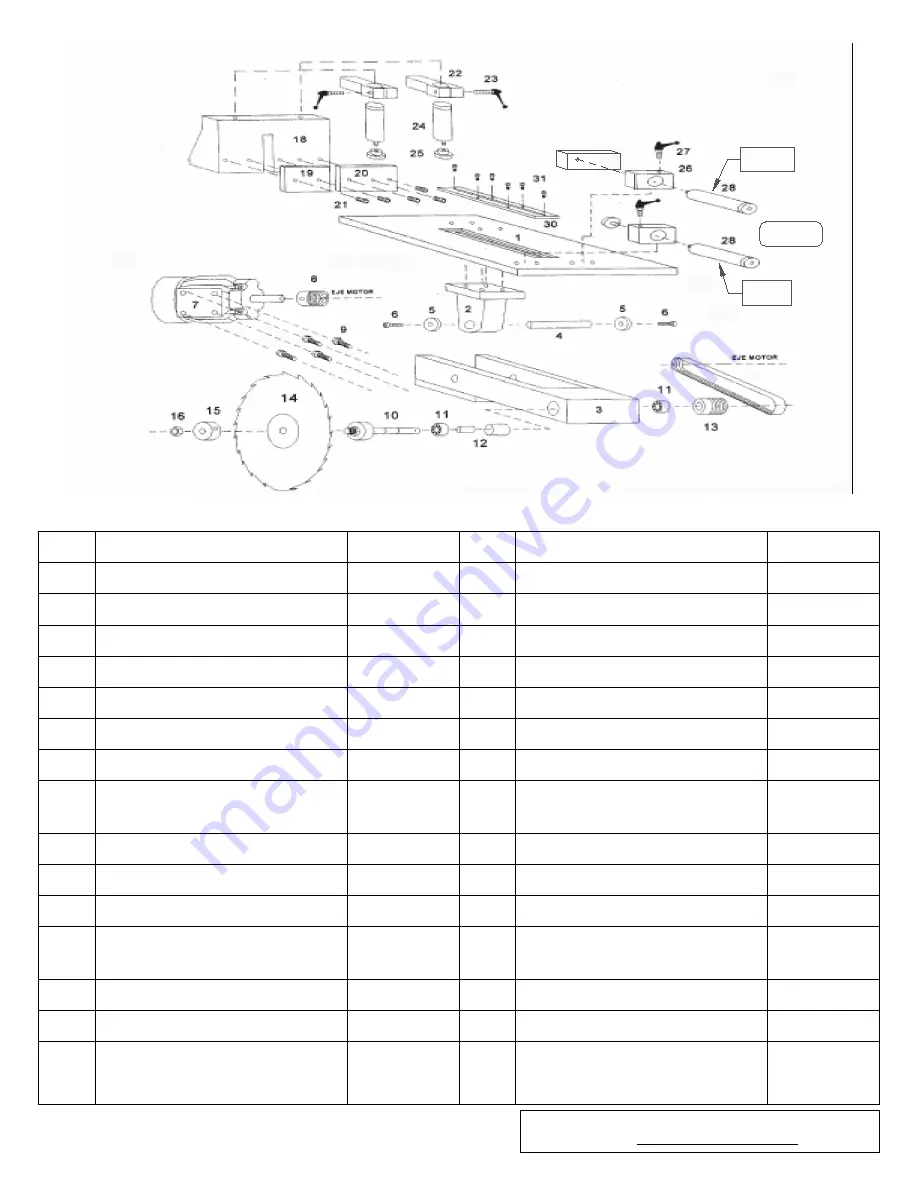

NO.

2

3

DESIGNATION

CODE NO.

1 WORKING PLATE

ROKER SUPPORT

ROKER

2059000064 17*

2050000322 18

DESIGNATION

POLY V 1016J BELT*

TURRET

2050000332 19 LEFT TURRET PLATE

4 ROKER ROTATION SHAFT 2040000072 20 RIGHT TURRET PLATE

5 WASHER M-12

6 DIN 912 M-12 X 25 PIN TD91212025 22

7

4 HP 3 PHASE MOTOR 2050000022 23 M-10 X 70 PULL

9 DIN 931 M-10 X 50 PIN TD93110050 25

4206 BEARING

SEPARATORS

NYLON CLEAT

2040000172 27 M-10 X 40 PULL

8 MOTOR PULLEY 2050000142 24 Ø 45 PNEUMATIC HOLD

DOWN CLAMP

TD12500012 21 DIN 6912 M-6 X 16 PIN TD69120616

Ø 45 ALUMINUM ROD 2040000062

B000001070

1677

2350000131

10 RECTIFIED Ø 100 SHAFT

2050000092 26 Ø 36 HORIZONTAL ROD 2090000191

11

12

28 Ø 36 X 225 PNEUMATIC

CLAMP

13

14

15

16

ROCKER PULLEY

2169000132 29

Ø 500 BLADE

205DW35032

BLADE WASHER

BLADE NUT

2050000032 31

2040000232

FIGURE 10

Page 24

30

GAA CLAMP BLOCK

BLADE GROOVE GAA-500

DIN 7991 M-6 PIN

B000006X40

C2070000295

2050000172

CODE

1283*

2059000024

29

LEFT SIDE

CLAMP

RIGHT SIDE

CLAMP

Also - See

Fig. 6 Page 17

17* - C2050000012 - J12 POLY V-BELT - Has '960 J' on the belt

Older 5.5hp saws use this belt

17*

5167

Summary of Contents for GAA-500-90 NF

Page 1: ...PRINTED OCTOBER 2020 Page 1 MODEL GAA 500 90 NF AUTO UPCUT COLD SAW WWW SCOTCHMAN COM...

Page 9: ...Page 9...

Page 11: ...Page 11 FIGURE 1...

Page 13: ...Page 13 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 15: ...Page 15 FIGURE 2 FIGURE 3...

Page 16: ...Page 16 FIGURE 5...

Page 17: ...Page 17 FIGURE 6...

Page 22: ...Page 22 POWER CIRCUIT FIGURE 8...

Page 23: ...Page 23 FIGURE 9...

Page 27: ...Page 27...

Page 29: ...Page 29 THIS PAGE LEFT BLANK INTENTIONALLY...

Page 31: ......

Page 32: ...Page 32 12 0 SHUTTLE FEED SYSTEM...

Page 33: ...Page 33...