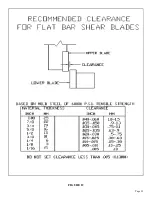

Page 26

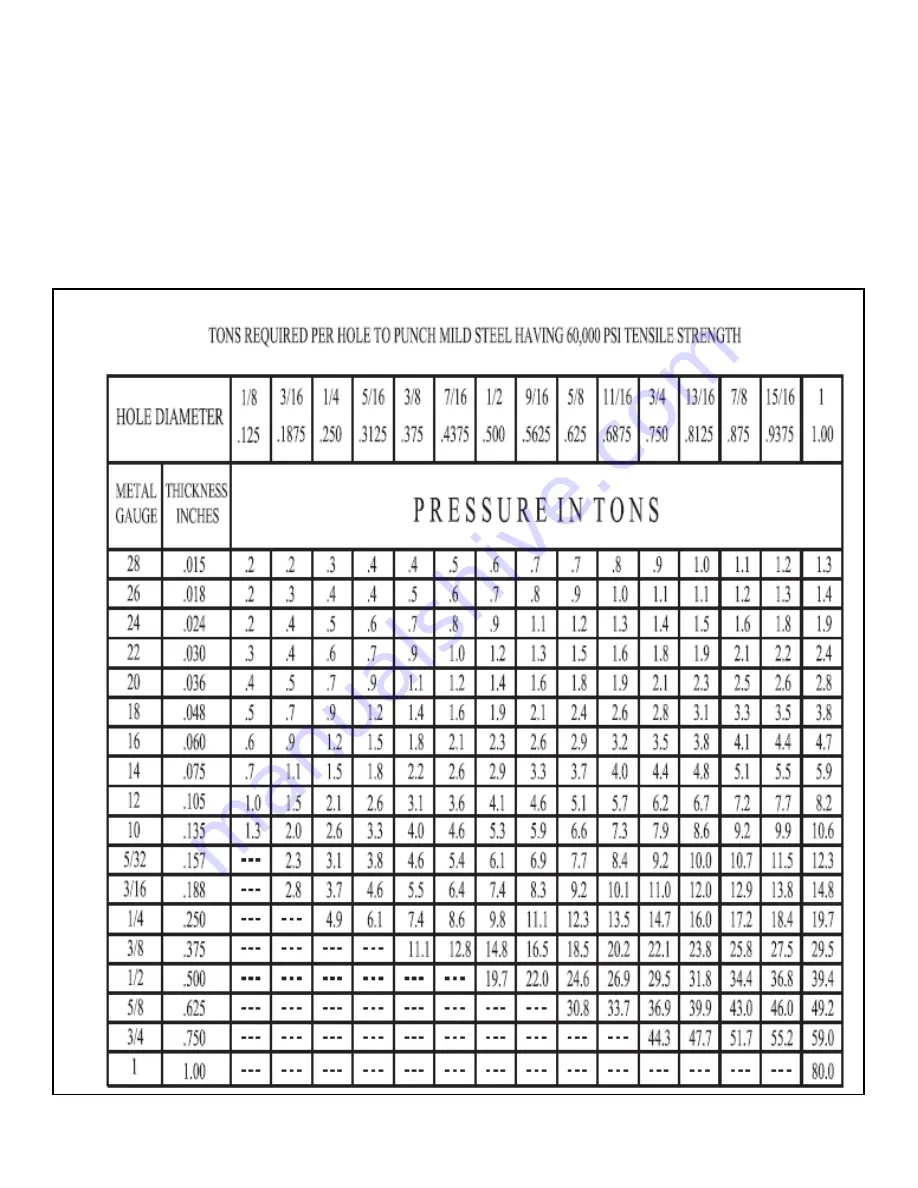

In mild steels, material thicknesses of 1/4 inch through 5/8 inch should have a total punch to die

clearance of 1/32 inch. (Punch di 1/32" = Die diameter.)

3/4 inch thick mild steel should have a minimum of 1/16 inch clearance. (Punch di 1/16" = Die

diameter.) In thin materials, the recommended punch to die clearance is 1/10 of the material thickness.

We do not recommend less than 1/64 inch total clearance, due to working clearances necessary in the

punch ram and the punch bushing.

For capacities, REFER TO THE PUNCH TONNAGE CHART IN FIGURE 9 BELOW.

FIGURE 9

Summary of Contents for IRONWORKER 6509-24M

Page 1: ...Page 1 MODEL 6509 24M IRONWORKER PRINTED MARCH 2005...

Page 9: ...Page 9 FIGURE 1...

Page 17: ...Page 17 FIGURE 5...

Page 19: ...Page 19 FIGURE 6...

Page 21: ...Page 21 FIGURE 7...

Page 31: ...Page 31 FIGURE 11...

Page 33: ...Page 33 FIGURE 12...

Page 35: ...Page 35 FIGURE 13...

Page 39: ...Page 39 FIGURE 15...

Page 41: ...Page 41 FIGURE 16...

Page 47: ...Page 47 FIGURE 20...

Page 51: ...Page 51 FIGURE 22...

Page 55: ...Page 55 FIGURE 25...

Page 59: ...Page 59 FIGURE 27...

Page 69: ...Page 69 FIGURE 30...

Page 71: ...Page 71 FIGURE 31...

Page 75: ...Page 75 FIGURE 34...

Page 79: ...Page 79 FIGURE 37...

Page 81: ...Page 81 FIGURE 38...

Page 85: ...Page 85 FIGURE 40 Serial s 5035FF1094 to 7124FF103...